-

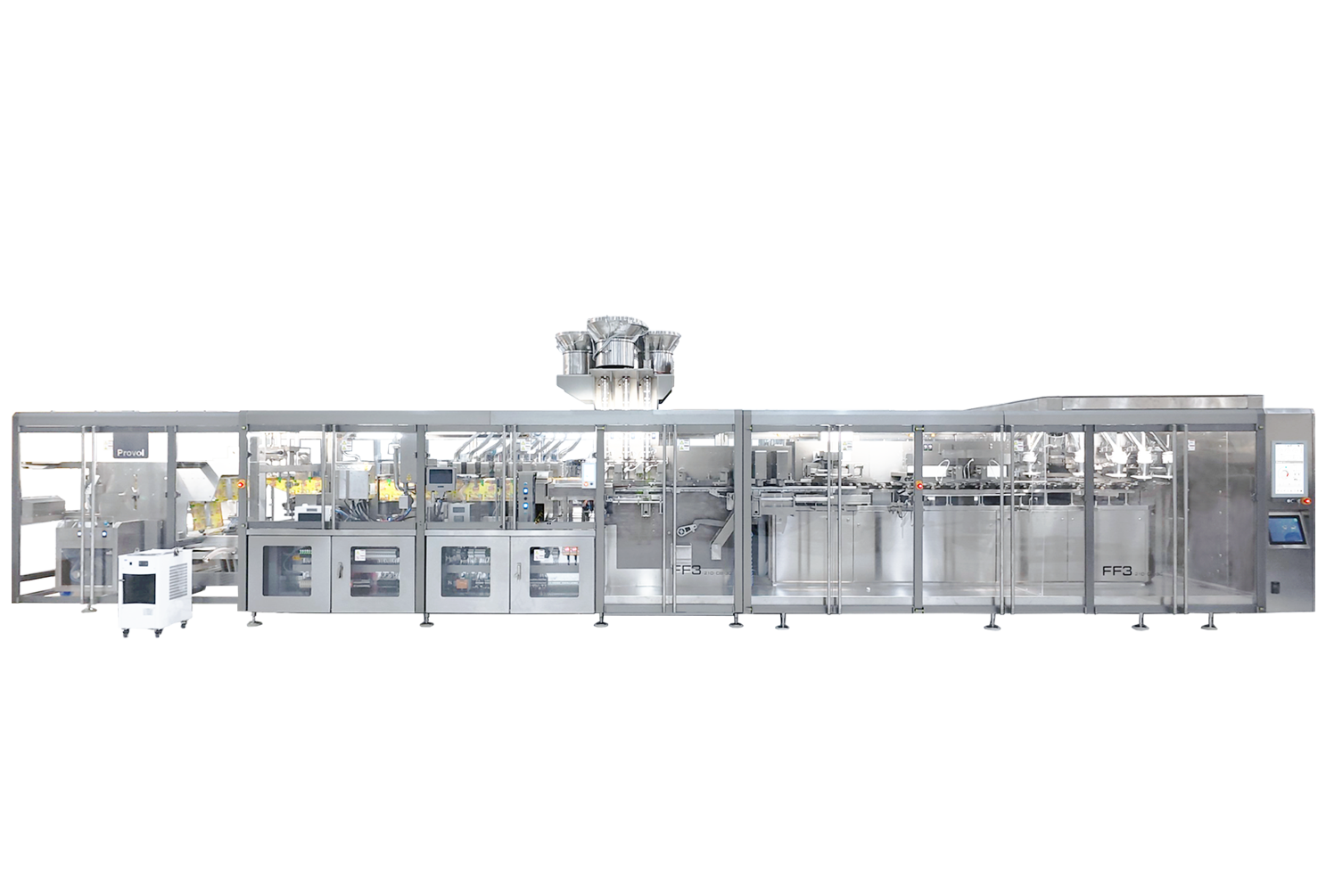

FF3-210-C8-3C

Package solution for lower cost and higher efficiency

- Continuous operation structure, with stable machine operation and better noise control; it can maintain a stable production rhythm during long-term continuous production, ensuring the efficiency of mass production.

- The packaging range covers from 100×140 mm to 205×320 mm, supporting quick changeover of various formats; It meets both high-volume production and multi-SKU flexible manufacturing needs, significantly reducing changeover time and avoiding redundant equipment investment.

- The integration of intelligent control and structural design significantly reduces the reliance on operational experience; effectively minimizes material waste and human error. This delivers a balanced optimization of labor costs, material consumption, and product consistency.

-

Characteristics

- Production Efficiency

Stable operation with high speed

The maximum speed can be up to 180 bags per minute, with high-speed and stable output, significantly improve the overall production capacity.

-

- Product quality

Auto adjustment of bag forming

Photoelectric technology enables online monitoring of bag forming quality, with real-time adaptive adjustment of the bag forming modules to ensure consistently precise bag opening.

-

- Quick changeover

Full servo system, auto adjustment of changeover

A full servo-driven control system enables precise motorized adjustment of over 80% of changeover points, significantly reducing changeover time and enhancing production flexibility.

-

- Cost saving

Less film loss

No film waste of vertical edge-cutting design, effectively reduces film waste and continuously lowers packaging costs.

-

- Product quality

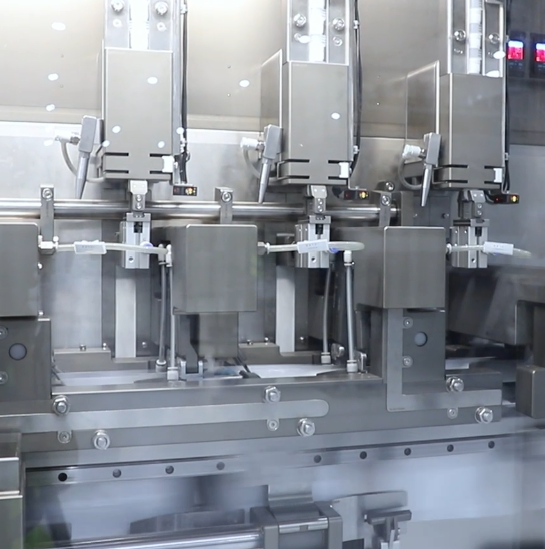

Multi-dimension camera detection

Key heat-sealing points, including cap sealing and top sealing, are monitored in real time to proactively detect abnormalities and consistently ensure sealing quality stability.

-

- Product quality

Multi-station for cap sealing

The multi-station cap sealing and flattening ensures both sealing strength and visual consistency, enhancing the product’s on-shelf appearance.

-

- Product quality

Adjust the filling accuracy online

Supports integration with checkweigher and other metering system, enabling real-time automatic correction of filling weight to ensure precise filling and reduce overfill losses.

-

Industries

Industries service

It can be linked with down stream check weigher and other metering devices to achieve real-time automatic adjustment of filling weight, ensuring more precise filling accuracy.

The quick connection technology of the hopper makes the hopper replacement faster and easier.

The machine reduce redundant plane and avoids exposed bolts and gas pipes, which is easier to clean.

The machine reserves multiple sealing stations ,ensures the quality and the appearance.

Industries service

The machine reserves multiple sealing stations ,ensures the quality and the appearance.

The cap adding module is an optional function and can be easy to manipulate.

It can be integrated with a doybag forming module, and various bag types such as three-side seal, four-side seal, and doybag can be changed quickly.

The automatic reel splicing system allows you to change running web rolls without stopping production.

Industries service

The quick connection technology of the hopper makes the hopper replacement faster and easier.

The machine reduce redundant plane and avoids exposed bolts and gas pipes, which is easier to clean.

Real-time detection of the key heat-sealing parts such as the cap sealing and top sealing, to ensure the sealing quality to the greatest extent.

It can be integrated with a doybag forming module, and various bag types such as three-side seal, four-side seal, and doybag can be changed quickly.

Industries service

It can be linked with down stream check weigher and other metering devices to achieve real-time automatic adjustment of filling weight, ensuring more precise filling accuracy.

Real-time detection of the key heat-sealing parts such as the cap sealing and top sealing, to ensure the sealing quality to the greatest extent.

The cap adding module is an optional function and can be easy to manipulate.

The automatic reel splicing system allows you to change running web rolls without stopping production.

Detailed parameters

-

- Filling Materials

- Solid, Fluid, Solid+Fluid, Powder

-

- Min. Pouch Size(Width x Height x Bottom)(mm)

- 100 x 140 x (25 x 2)

-

- Max. Pouch Size(Width x Height x Bottom)(mm)

- 205 X 320 X (50 X 2)

-

- Speed Range(pouch/min.)

- 150-180(Actual speed depends on the properties of specific filling materials.)

-

- Voltage

- AC380V

-

- Frequency(Hertz)

- 50HZ/60HZ

-

- Power

- 15KW

-

- Air Consumption (m³/min)

- 0.6-1.5

-

- Noise Index

- <80dB

-

- Machine Dimension(L x W x H) (mm)

- 15,056x2,035x2,350

-

- Net Weight (kg)

- 14,000

More equipment

-

-

-

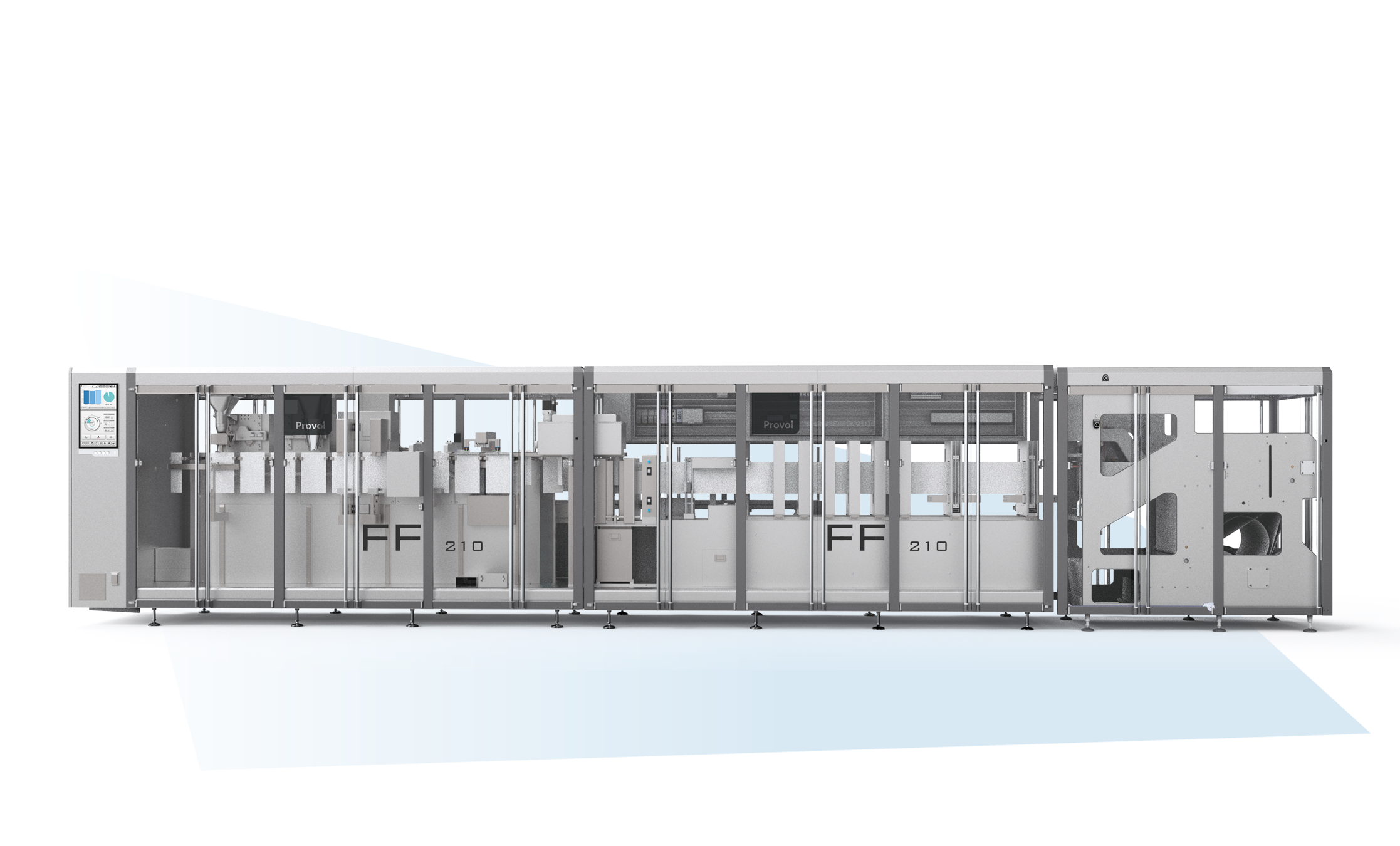

FF-210-I2

The speed range of flexible high-speed packaging machine FF210-I2 is 80-120 ppm The pouch sizes range: min size as 100(W)×140(H)mm, max size as 205(W)×320(H)mm.

FF210-I2 runs continuously and stably for a long time, the fastest output can be up to 9000-18000 pouches per hour.

-

-

-

-

FF-210-C8

The speed range of flexible high-speed packaging machine FF210-C8 is 100-160 ppm.

The pouch sizes range: min size as 100(W)×140(H)mm, max size as 205(W)×320(H)mm.

FF210-C8 runs continuously and stably for a long time, the fastest output can be up to 9600 pouches per hour.

Large output, on-line pouch manufacture from roll film, the value can be calculated.

-