-

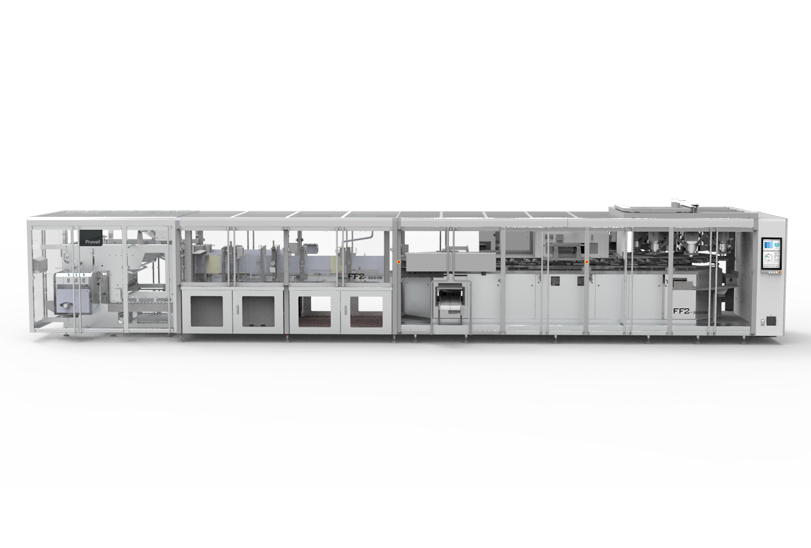

FF2-320-C8

Stable output and flexible response

- Stable High-Speed Performance Even for Large Formats

- Even when handling large-format packages such as 1 kg bags, the machine maintains continuous and stable operation—balancing speed, reliability, and production line continuity.

- Online Monitoring and Automatic Adjustment for Consistent Quality

- The bag forming and filling processes are continuously monitored and automatically adjusted in real time, ensuring precise bag shaping, consistent sealing, and controlled filling performance.

- Full Servo Drive for Faster and More Efficient Changeover

- Over 80% of changeover adjustments are completed automatically via the servo system, significantly reducing downtime when switching between different formats.

-

Characteristics

- Production Efficiency

High speed and stable operation

Even when handling large-format packages of up to 1 kg, the machine maintains stable operation at speeds of up to 120 bags per minute, delivering both continuity and reliability at high speed and consistently maximizing overall line efficiency.

-

- Product Quality

Intelligent adjustment of bag forming

Through photoelectric technology, the pouch forming process is monitored online in real time. The pouch forming module is dynamically adjusted in linkage to effectively control pouch accuracy and forming consistency, ensuring long-term stability of finished product quality.

-

- Quick Changeover

Full servo quick changeover

A fully servo-driven control structure enables more than 80% of format changeover adjustments to be precisely executed by servo motors, significantly reducing changeover time and improving overall efficiency for multi-format, small-batch production.

-

- Product Quality

Filling with vibration

The servo vibration function applies high-frequency vibration to the bottom of the pouch, ensuring smoother filling, more uniform material distribution, and improved pouch fullness, while reducing quality fluctuations caused by uneven filling.

-

- Space Usage

Bidirectional bag-out design

The bag discharge direction supports flexible bidirectional switching and can be adjusted according to different production line layouts and on-site space requirements, enhancing operational flexibility while improving overall space utilization.

-

Industries

Industries service

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

The punching module is an optional function to meet all the needs of European holes,easy tear holes,etc.

Automatic adjustment according to different size of bags,the changeover can be completed in a very short time.

The automatic reel splicing system allows you to change running web rolls without stopping production.

Industries service

The liquid filling nozzle can be adjusted at multiple angles and opened and closed at high speed. This makes the liquid filling process more stable and efficient.

The machine reduce redundant plane and avoids exposed bolts and gas pipes, which is easier to clean.

The punching module is an optional function to meet all the needs of European holes,easy tear holes,etc.

It can be matched with laser, inkjet, heat transfer and other types of coding, and can be matched with quick adjusted mounting brackets.

Industries service

Servo bag vibrating function makes the filling process more smooth and the materials more even.

The punching module is an optional function to meet all the needs of European holes,easy tear holes,etc.

The machine can be integrated with online zipper function without speed loss.

The automatic reel splicing system allows you to change running web rolls without stopping production.

Industries service

The quick connection technology of the hopper makes the hopper replacement faster and easier.

The bag feeding system controlled by multiple servo motors can realize high-speed production regardless of packaging type and material.

It can be matched with laser, inkjet, heat transfer and other types of coding, and can be matched with quick adjusted mounting brackets.

The automatic reel splicing system allows you to change running web rolls without stopping production.

Detailed parameters

-

- Filling Materials

- Solid, Fluid, Solid+Fluid, Powder

-

- Min. Pouch Size(Width x Height x Bottom)(mm)

- 130 x 200 x (25 x 2)

-

- Max. Pouch Size(Width x Height x Bottom)(mm)

- 320 X 320 X (50 X 2)

-

- Speed Range(pouch/min.)

- 80-120(Actual speed depends on the properties of specific filling materials.)

-

- Voltage

- AC380V

-

- Frequency(Hertz)

- 50HZ/60HZ

-

- Power

- 15KW

-

- Air Consumption (m³/min)

- 0.6-1.5

-

- Noise Index

- <80dB

-

- Machine Max Dimension(L x W x H) (mm)

- 13,061x2,475x2,315

-

- Net Weight (kg)

- 16,500

More equipment

-

-

-

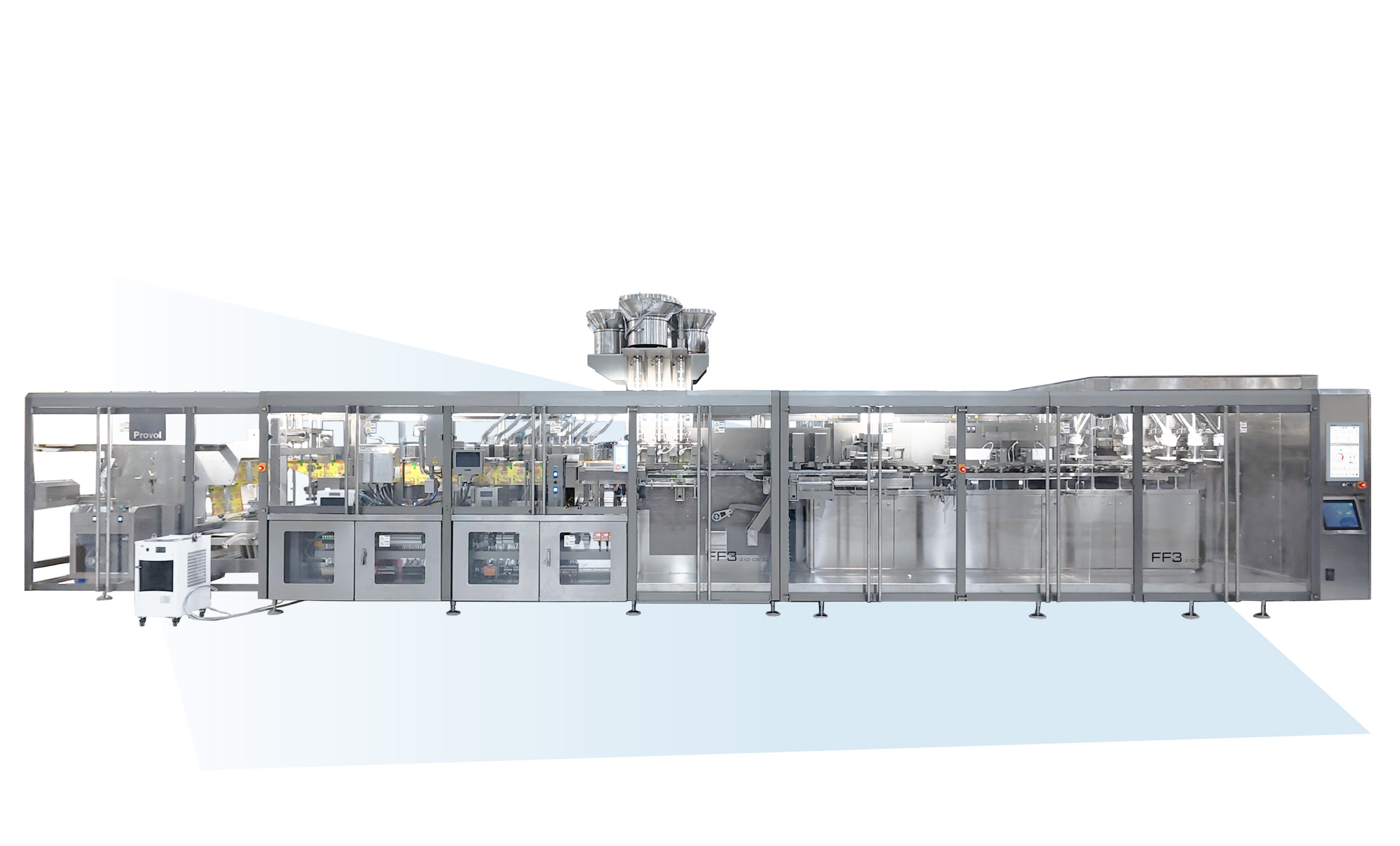

FF3-210-C8-3C

The speed range of flexible high-speed packaging machine FF3-210-C8-3C is 150-180 ppm.

The pouch sizes range: min. size as 100(W)×140(H)mm, max. size as 205(W)×320(H)mm.

Overcoming the pain points of the industry from production efficiency, labor cost, material loss, and quality assurance. Whether mass production or multi-specification flexible orders, it can provide one-step packaging solutions for food and beverage, condiments, pet food, and other industries.

-

-

-

-

FP3-320-C8

The speed range of flexible high-speed packaging machine FP3-320-C8 is 60-100 ppm.

The pouch sizes range: min size as 130(W)×200(H)mm, max size as 320(W)×600(H)mm.

Continuous operation, high-speed and more stable;

large-span automatic adjustment to meet more possibilities

-