-

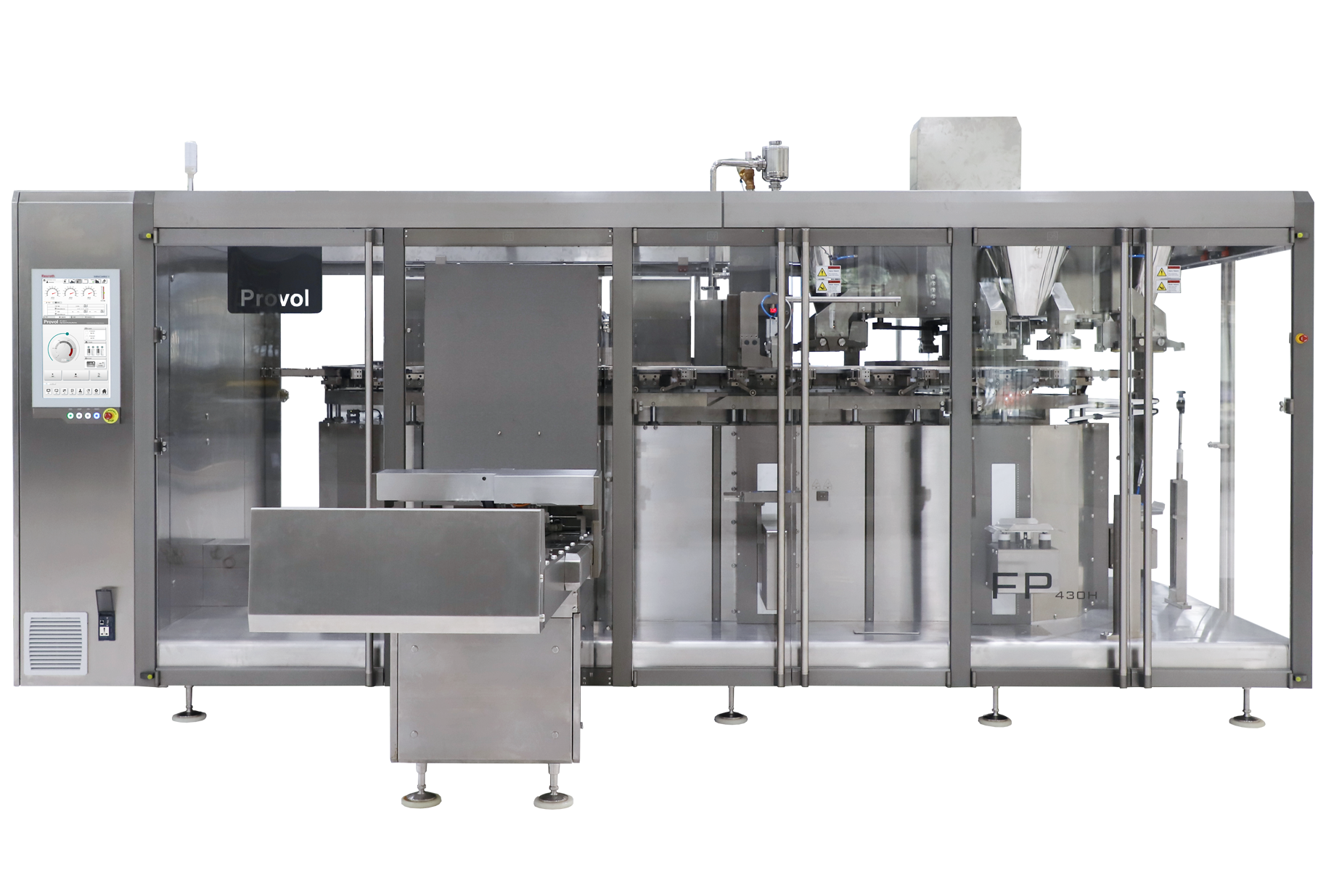

FP-430H-I1

Once Investment, Multiple Returns

- The continuous following filling module - much faster, more stable, and no time limited to fill the products.

- Exquisite workmanship - high-quality features with Provol

- Wide format range - from min bag width as 165mm to max bag width as 430mm.

- 4 Side Seal Bags

- A 4-side-seal bag is also known as a flat bag. A small 4-sided sealed bag is also known as a pouch. This bag format is a good choice when uniformity of packaging is a priority. For example, in some cases, multiple 4-sided Ziploc bags are further packaged in a folded carton or a box. The box is then displayed on the shelf for retail sale, allowing consumers to purchase multiple packages in a single carton. Such bags are formed by sealing the front and back panels of the bag through the perimeter of the bag. In other words, all 4 sides of the bag are sealed. Compared to pillow bags, these bags cannot bend, deform or expand like pillow bags. By sealing all four sides of the bag, it provides better security against leakage. This style is popular for liquid products and sample bags. Brand information can be filled in on the front and back panels.

- Benefits of four-side-seal bags:

- Economical flexible packaging option

- Good packaging security to prevent spills

- Good packaging uniformity for easy boxing

- Tear notch for easy access to product

- Can be used for high speed packaging applications

- Economical storage and transportation

- Gravure printing in up to 10 colors

- Glossy, matte or UV finish

- Available in metallized and non-metallized material constructions

-

Characteristics

- Easy to operate

Friendly interface

The online weighing module, bag loading detection, bag height detection, coding detection and other sets of detection will accurately monitor OEE of the whole machine in real time, and display the data on HMI, which accurately control product quality.

-

- Production Efficiency

Continuous and stable production output

The multiple filling station, which is 4.5 times longer than the filling time on the traditional machine.

-

- Quick changeover

Meet wide format range

Recipes design for production changeover, all of the parts for each changeover are clear at a glance, and changeover time is recorded in real time, which provides any possibility to continuously optimize the efficiency of production changeover.

-

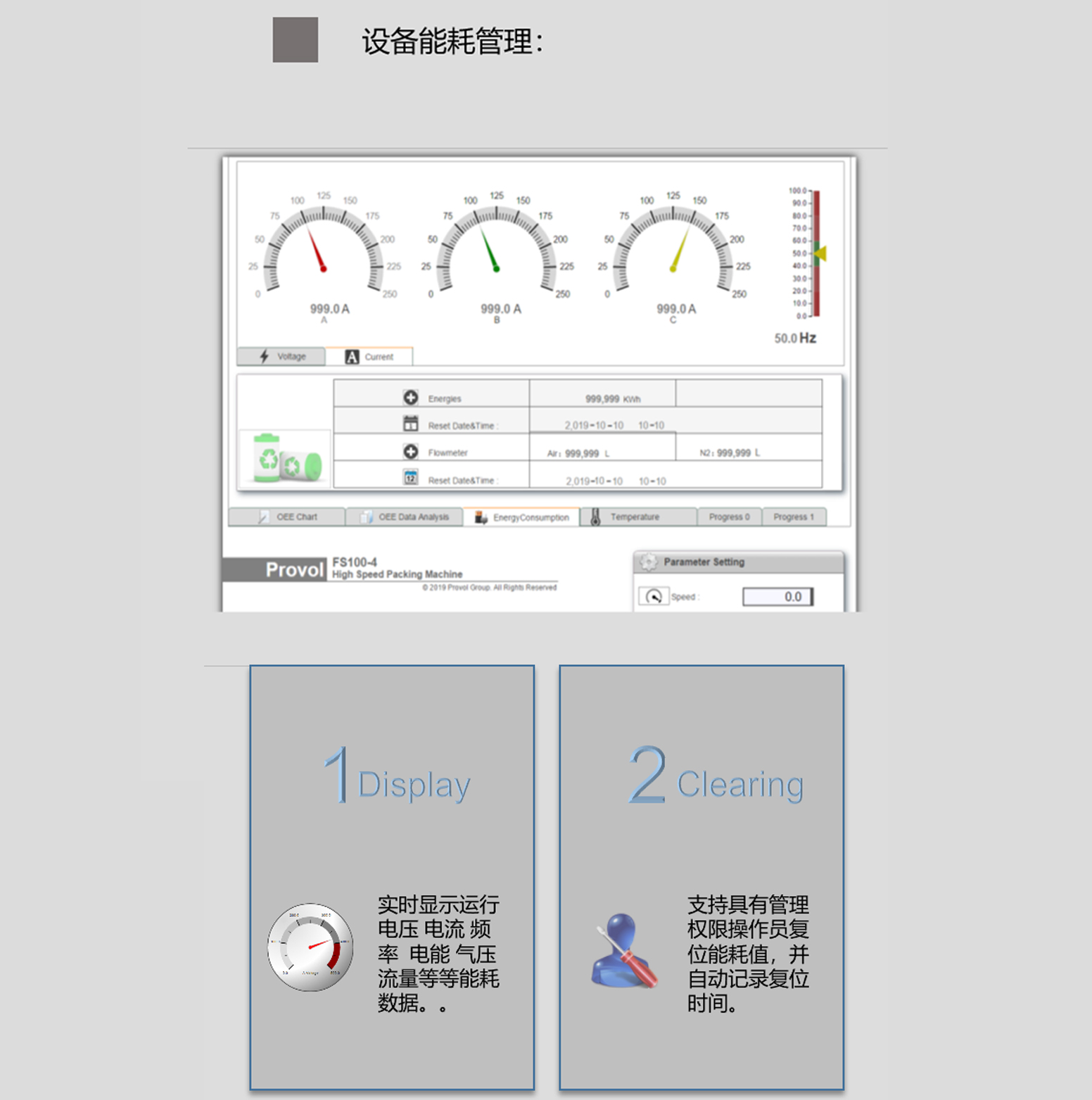

- Cost saving

Groundbreakingtechnology reduces energy consumption

Full servo drive control, each axis movement is started on demand, which greatly reduces the power consumption when the machine is running.

The touch screen will display the running status in real time, and monitor the energy consumption such as voltage, current, air pressure flow and so on, that will achieve the precise control. -

- Space usage

More compact space

Rotary cycle chain structure, using rotating space for filling the products.

-

- Product quality

System closed-loop quality control

The online weighing module, bag loading detection, bag height detection, coding detection and other sets of detection will accurately monitor OEE of the whole machine in real time, and display the data on HMI, which accurately control product quality.

-

- Health and Safety

Less hygienic dead corner

The F series packaging machine is designed according to Provol hygienic design standard. High sealing feature of the machine driving part, no hygienic dead corner for the exposed mechanical assemblies, and the air tube wiring is hidden into the structure, that is easy to clean.

For some parts that need to be removed to clean and replace such as the teflon cloth of sealing jaws, conveyor belt, etc., which are quickly cleaned and no tools needed. -

Industries

Industries

Bag-Bottom vibrating makes the filling process more smooth and the materials more even.

The vacuum system is equipped with a filtering device, which can be quickly cleaned and replaced, so that the equipment maintenance is simpler.

The level and height of the packaging bag can be detected online, so that the quality and appearance of the final product can be more guaranteed.

The bag suppling system controlled by multiple servo motors can realize high-speed production regardless of packaging type and material.

Industries

液体灌装喷头可实现多角度调整,高速开启关闭,液体灌装过程更稳定、高效。

可匹配设计缓存罐供料系统,搭配容积式计量设备及卫生级管路,实现产品的精确供给。

整体平面设计,避免外露螺栓、气管,更便于清洁。

可匹配激光、喷墨、热转印等多种打码形式,并匹配快速调整的安装支架,实现高质量打码和快速换产。

Industries

伺服震袋功能, 通过对包装底部进行震动,使得充填过程更加流畅,充填后物料更均匀。

可配置在线称重功能,保证产品重量实时监控反馈,产品包装精度更高,物料成本大幅降低。

可配置高速拉链打开装置,即使是拉链袋也能实现高速包装。

真空系统自带过滤装置,可快速实现清洁和更换,设备维护更加简单。

Industries

Automatic adjustment seal jaws position and pouch grippers adjustment,Make your format change in a very short time.

It can be compatible with multihead weigher, linear weigher and other weighing equipment. It can be quickly docked, easily disassembled and cleaned.

The machine reduce redundant plane and avoids exposed bolts and gas pipes, which is easier to clean.

The level and height of the packaging bag can be detected online, so that the quality and appearance of the final product can be more guaranteed.

Detailed parameters

-

- Filling Materials

- Solid, Fluid, Solid+Fluid, Powder

-

- Min. Pouch Size(Width x Height x Bottom)(mm)

- 170 x 300 x (25 x 2)

-

- Max. Pouch Size(Width x Height x Bottom)(mm)

- 430 X 800 X (75 X 2)

-

- Speed Range(pouch/min.)

- 20-50(Actual speed depends on the properties of specific filling materials.)

-

- Voltage

- AC380V

-

- Frequency(Hertz)

- 50HZ/60HZ

-

- Power

- 7.5kW

-

- Air Consumption(m³/min)

- 0.6-1.5m3/min

-

- Noise Index

- <80dB

-

- Machine Dimension(L x W x H)(mm)

- 5,212 X 2,000 X 2,150

-

- Machine Max Dimension(L x W x H)(mm)

- 5,304 X 5,063 X 2,600

More equipment

-

-

-

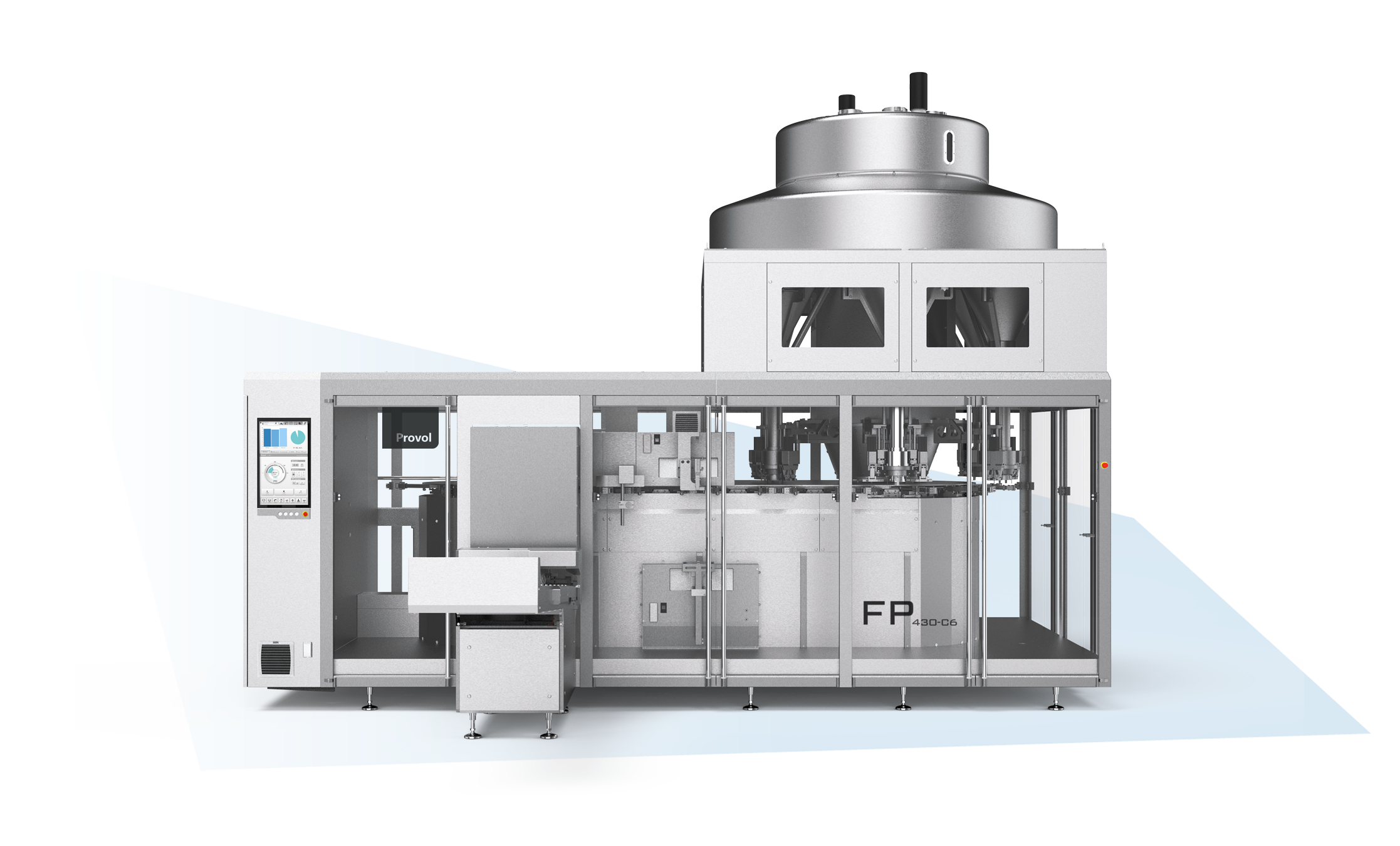

FP-430-C6

The speed range of flexible high-speed packaging machine FP430-C6 is 20-60 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×600(H)mm.

The machine FP430-C6 has complete functions and good performance for continuous and stable production output.

-

-

-

-

FP-430L-I1

The speed range of flexible high-speed packaging machine FP430L-I1 is 10-40 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×1000(H)mm.

Wide format range of the machine FP430L-I1 is from min 165mm to max 430mm, the max bag height can be up to 1 meter.

-