-

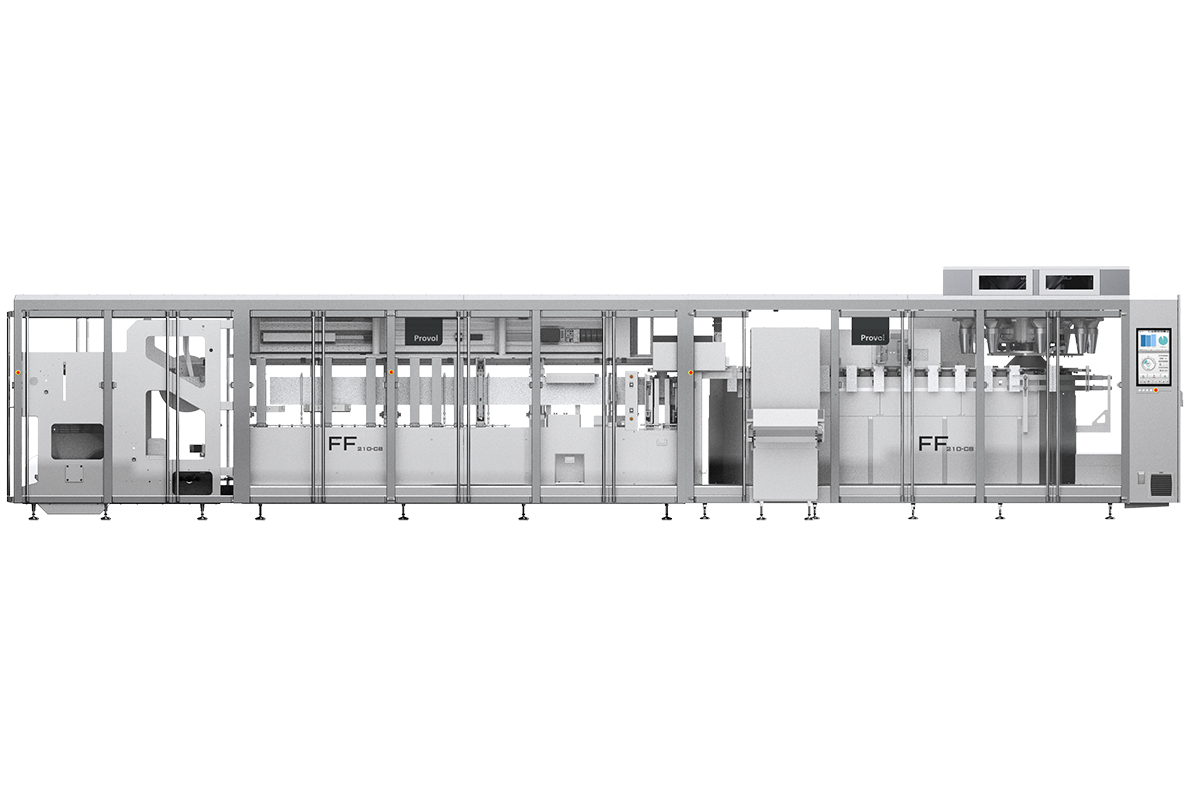

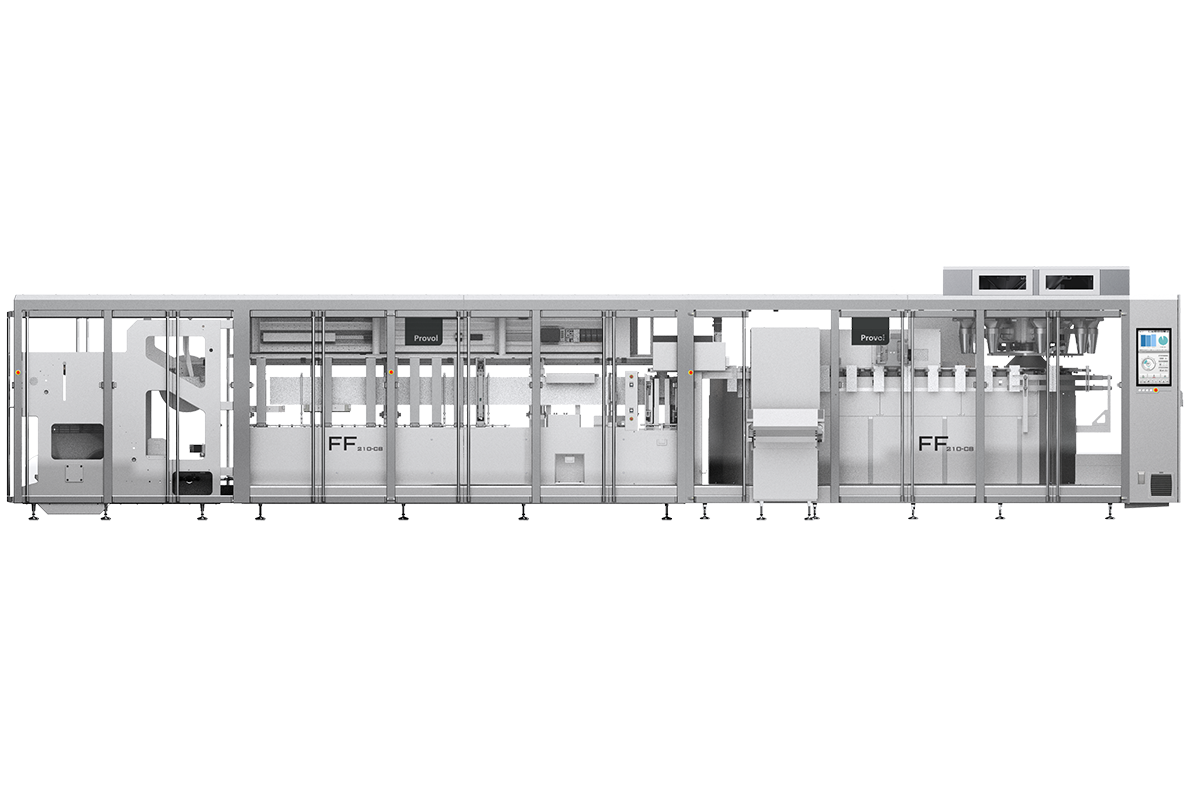

FF-210-C8

Much High Comprehensive Efficiency, Optimal Model Choose

- Stable performance - continuous motion mode, lower noise.

- High-speed output, which can be up to 9600 pouches per hour at the fastest.

- Online pouches manfacture from roll film, and custom design for creative special shape pouches.

-

Characteristics

- Production Efficiency

The Secret of Serial Production

This flexible high-speed packaging machine utilizes the power of advanced servo drive technology, and the movement of each axis is started on demand, which greatly reduces the power consumption of the machine when it is running.

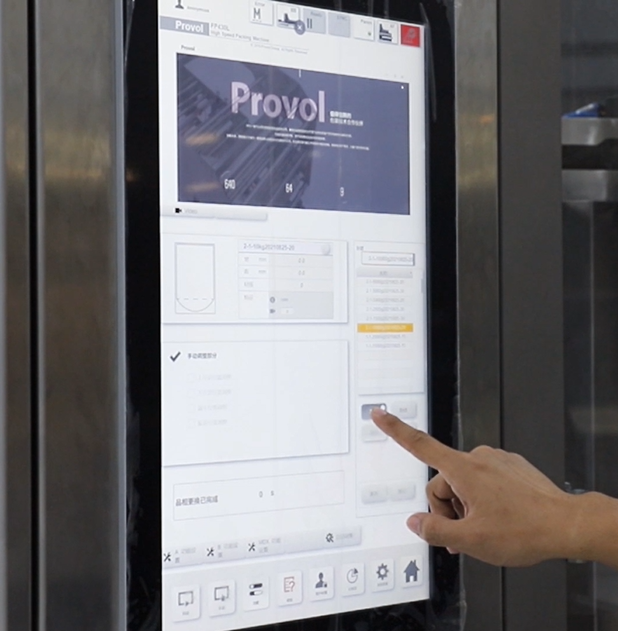

The touch screen displays the running status in real time, monitors energy consumption such as voltage, current, air pressure flow, etc., and realizes precise control. -

- Quick changeover

Free changeover for multiple SKU

Recipes design for production changeover, all of the parts for each changeover are clear at a glance, and changeover time is recorded in real time, which provides any possibility to continuously optimize the efficiency of production changeover.

All of the changeover parts adopt the quick disassembly structure, which can custome design all of the neccessary accessories according to the customers various SKU production. -

- Product quality

Minimize defective products

The online weighing module, bag loading detection, bag height detection, coding detection and other sets of detection will accurately monitor OEE of the whole machine in real time, and display the data on HMI, which accurately control product quality.

-

- Easy to operate

Full Automation, Easier Operation.

The online weighing module, bag loading detection, bag height detection, coding detection and other sets of detection will accurately monitor OEE of the whole machine in real time, and display the data on HMI, which accurately control product quality.

-

- Cost saving

High Volume, decrease film and cost reduction

Unleash unparalleled packaging capabilities with our flexible high-speed machine. Experience heightened output rates, while simultaneously minimizing film consumption and slashing costs. This cutting-edge innovation optimizes production efficiency, ensuring your operations remain at the forefront of competitiveness. Through precision engineering, it drastically reduces film waste, contributing to a sustainable future. Embrace cost reduction as streamlined operations enhance profitability. Driven by advanced servo technology, it intelligently manages energy consumption. The user-friendly touch screen provides real-time insights, empowering informed decision-making. Elevate your packaging endeavors – where exceptional output, minimized film usage, and cost efficiency seamlessly intertwine for ultimate success.

-

- Space usage

Flexible space due to functional integration

Rotary cycle chain structure, using rotating space for filling the products.

-

Industries

Industries

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

Serve bag vibrating function makes the filling process more smooth and the materials more even.

The punching module is an optional function to meet all the needs of European holes,easy tear holes,etc.

The machine can be integrated with online zipper function without speed loss.

The automatic reel splicing system allows you tu change running web rolls without stopping production.

Industries

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

The camera detection function can be configured and detect printing quality, content, QR code, barcode and other contents online.

Pre-made pouch supply module enables you to produce both pre-made pouch and film forming on a single machine.

The packaging can be formed through die-cut function, which can meet the customized design.

Automatic adjustment seal jaws position and pouch grippers adjustment,Make your format change in a very short time.

Industries

Built in cyclone separator, which can easily realize waste recycling and separation.

The cap adding module is an optional function and can be easy to manipulate.

The machine can be integrated with online zipper function without speed loss.

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

The de-air system is effcient through vaccum and mechanical extrusion,which can ensures the transportation and safety of the product.

Industries

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

The cap adding module is an optional function and can be easy to manipulate.

The punching module is an optional function to meet all the needs of European holes,easy tear holes,etc.

The machine can be integrated with online zipper function without speed loss.

Various bag types can be forming and quickly switched.

Detailed parameters

-

- Min. Pouch Size(Width x Height x Bottom)(mm)

- 100 x 140 x (25 x 2)

-

- Max. Pouch Size(Width x Height x Bottom)(mm)

- 205 X 320 X (50 X 2)

-

- Speed Range(pouch/min.)

- 120-180(Actual speed depends on the properties of specific filling materials.)

-

- Voltage

- AC380V

-

- Frequency(Hertz)

- 50HZ/60HZ

-

- Power

- 15kW

-

- Air Consumption(m³/min)

- 0.6-1.5

-

- Noise Index

- <80dB

-

- Machine Dimension (L x W x H) (mm)

- 11570 X 2000 X 2150

-

- Machine Max Dimension (L x W x H) (mm)

- 11660 X 2205 X 2150

-

- Filling Materials

- Solid, Fluid, Solid+Fluid, Powder

More equipment

-

-

-

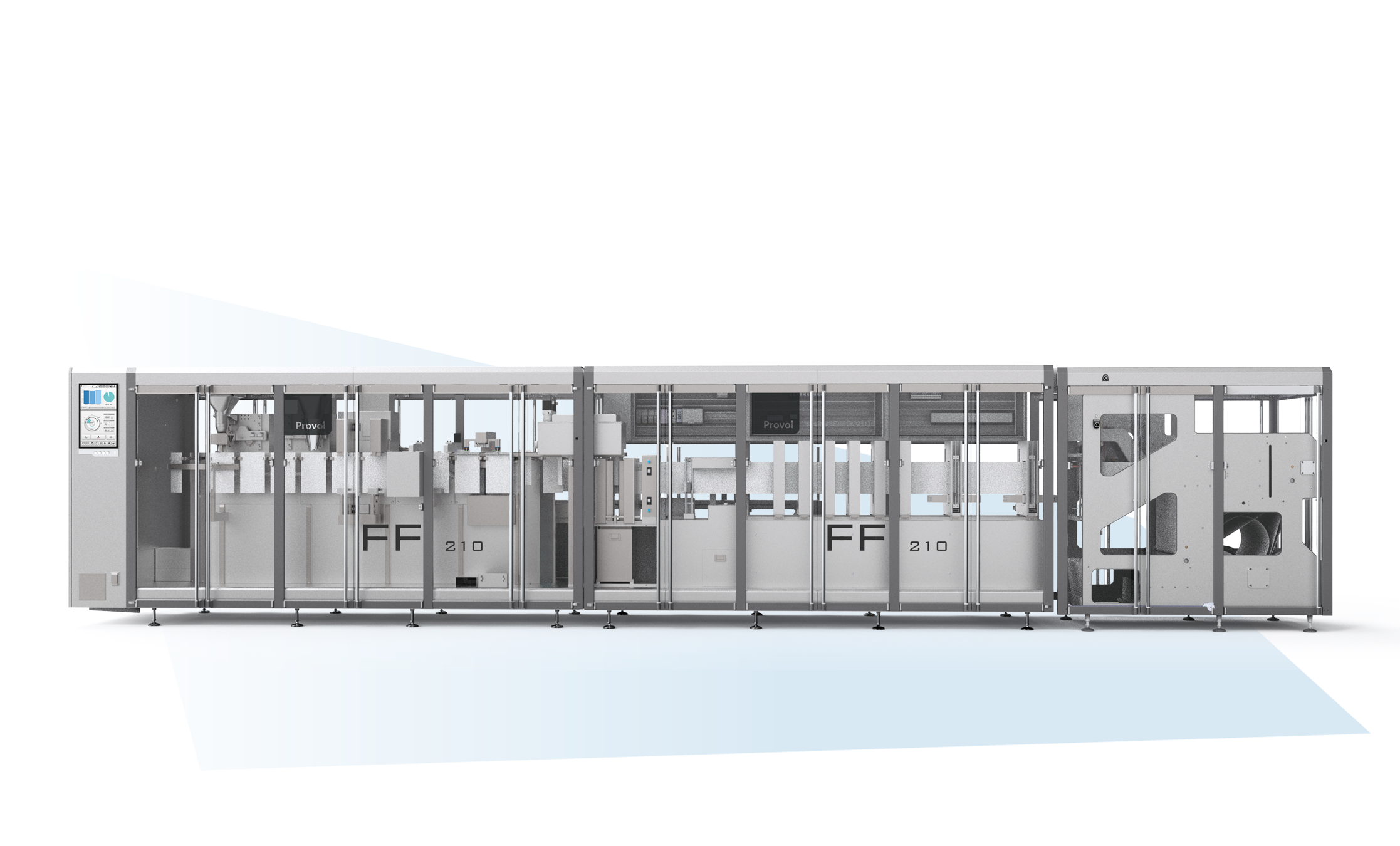

FF-210-I2

The speed range of flexible high-speed packaging machine FF210-I2 is 80-120 ppm The pouch sizes range: min size as 100(W)×140(H)mm, max size as 205(W)×320(H)mm.

FF210-I2 runs continuously and stably for a long time, the fastest output can be up to 9000-18000 pouches per hour.

-

-

-

-

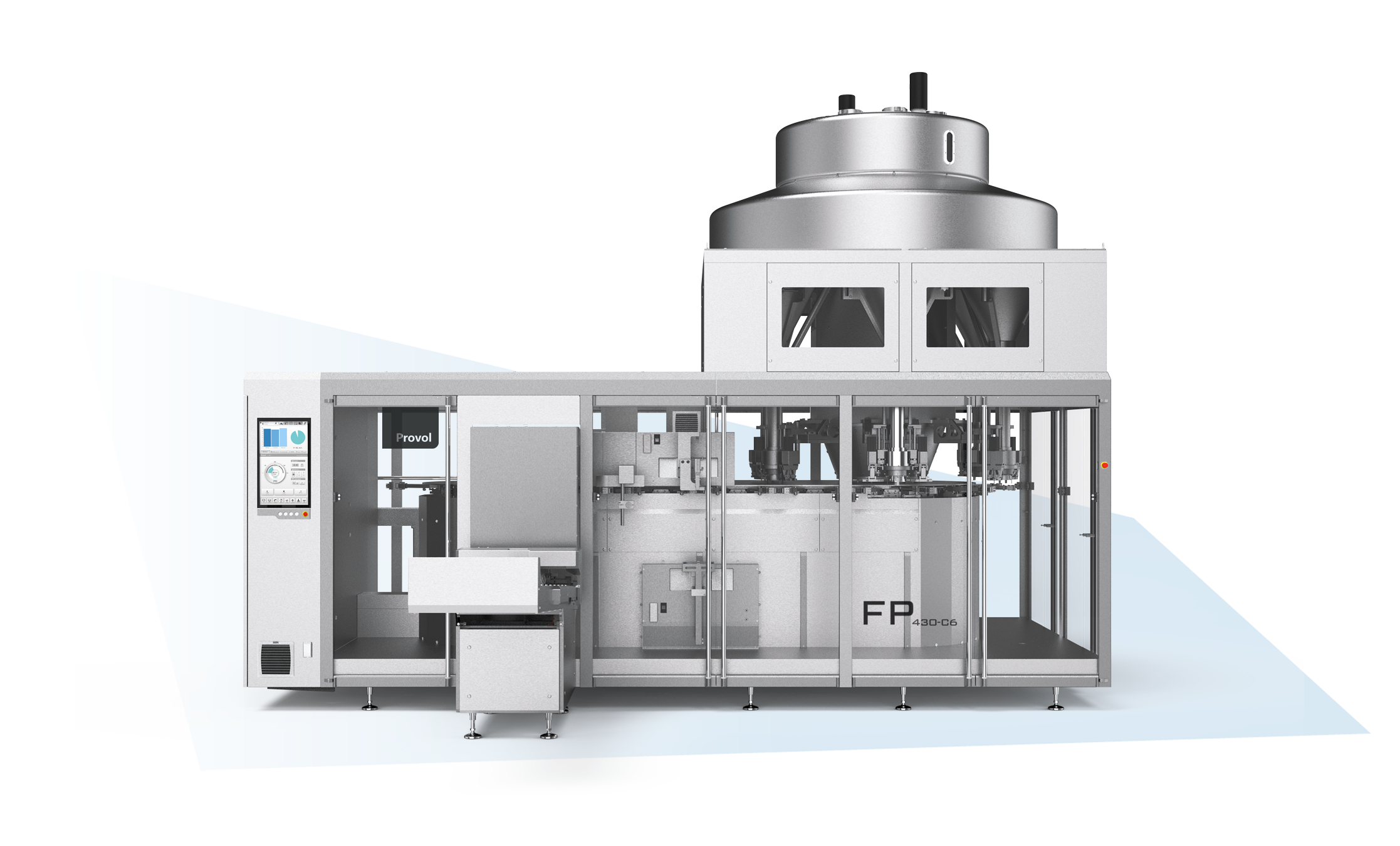

FP-430-C6

The speed range of flexible high-speed packaging machine FP430-C6 is 20-60 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×600(H)mm.

The machine FP430-C6 has complete functions and good performance for continuous and stable production output.

-