-

FP-430L-I1

Large Wide Format Range, Best Choice

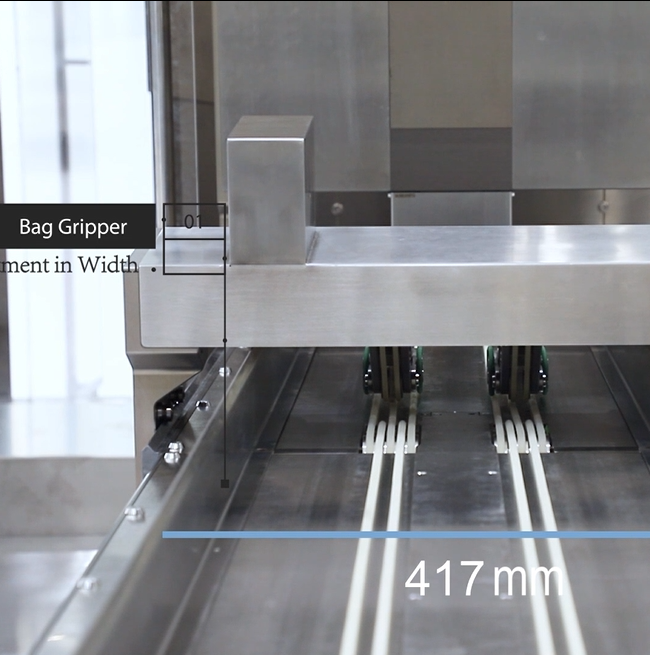

- Larger format range - from min bag width as 165mm to max bag width as 430mm. , and the max bag height can be up to 1 meter.

- Online nitrogen flush to keep the product freshness and flexbile vitality, whichi is suitabel for different SKU quick changeover.

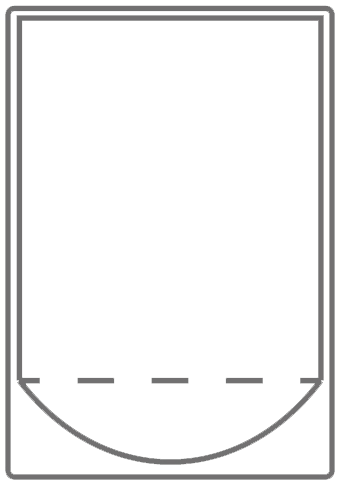

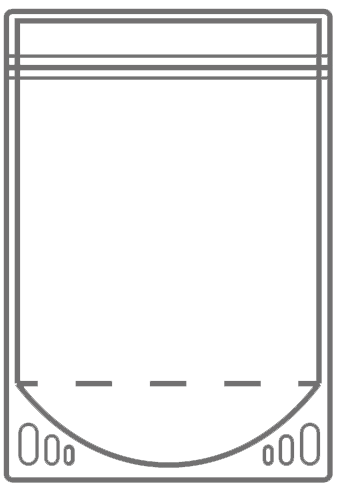

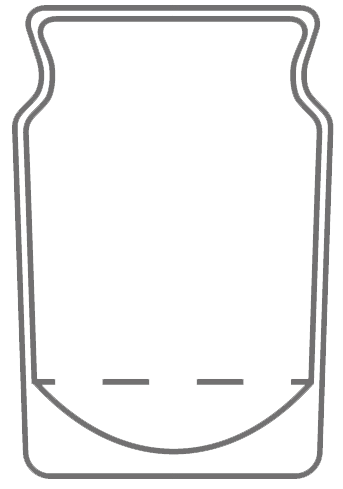

- Flexible pouch packaging machine, also known as pouch packaging machine, is used to pack various types of products into flexible pouches or pouches. These machines are commonly used in the food, pharmaceutical, cosmetic and other industries to package various items.

- Provol's automatic bag fill and seal machines can handle virtually all bag types and sizes including stand up pouches, flat pouches, zipper pouches, spout pouches, retort pouches, 3-side seal pouches, 4-side seal pouches, gusseted pouches, Pillow bags, multi-compartment bags, powder bags, liquid bags and more

- Provol offers a variety of flexible pouch packaging systems. The F-Series packaging machines are designed according to Provol hygienic design standards. The transmission part of the machine is highly sealed, and the exposed mechanical components have no hygienic dead ends, and the gas pipe wiring is hidden in the structure, which is easy to clean.

-

Characteristics

- Quick changeover

Quick changeover, less downtime.

Smaller floor space, more reserved workstations. The multi-station follows the blanking to increase the blanking time, which greatly increases the overall space efficiency.

-

- Easy to operate

Get production data at a glance

Multiple detection feedback functions such as bag loading, bag loading height and coding detection can more accurately monitor the OEE efficiency of the overall machine, and display it on the HMI in real time. The HMI adopts a new UI design concept, which can support multi-users browsing, display statistical production data and machine operating status.

-

- Production Efficiency

Stable operation for a long time

Full servo drive control, each axis movement is started on demand, which greatly reduces the power consumption when the machine is running.

The touch screen will display the running status in real time, and monitor the energy consumption such as voltage, current, air pressure flow and so on, that will achieve the precise control. -

- Health and Safety

Food grade hygiene standards

The F series packaging machine is designed according to Provol hygienic design standard. High sealing feature of the machine driving part, no hygienic dead corner for the exposed mechanical assemblies, and the air tube wiring is hidden into the structure, that is easy to clean.

For some parts that need to be removed to clean and replace such as the teflon cloth of sealing jaws, conveyor belt, etc., which are quickly cleaned and no tools needed. -

- Product quality

Multiple inspections ensure product quality

The online weighing module, bag loading detection, bag height detection, coding detection and other sets of detection will accurately monitor OEE of the whole machine in real time, and display the data on HMI, which accurately control product quality.

-

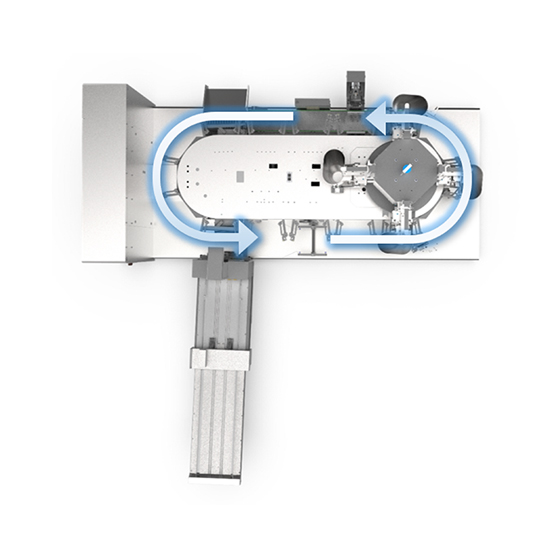

- Space usage

Flexible space due to functional integration

Rotary cycle chain structure, using rotating space for filling the products.

-

Industries

Industries

多个伺服电机控制的供袋系统,无论是任何型式、材质的包装,均可在全伺服供袋系统上实现高速生产。

在线实现对包装袋的水平、高度进行检测,使得最终产品质量和外观得到更多一份保证。

可匹配激光、喷墨、热转印等多种打码形式,并匹配快速调整的安装支架,实现高质量打码和快速换产。

整机超高兼容性,品相更换功可全部实现自动调整,换产更快更精准。

伺服震袋功能, 通过对包装底部进行震动,使得充填过程更加流畅,充填后物料更均匀。

Industries

在线实现对包装袋的水平、高度进行检测,使得最终产品质量和外观得到更多一份保证。

整体平面设计,避免外露螺栓、气管,更便于清洁。

可匹配设计缓存罐供料系统,搭配容积式计量设备及卫生级管路,实现产品的精确供给。

可配置固定式或跟随式灌装方式,满足多个液体灌装喷头同时灌装,速度更快,运行更平稳。

液体灌装喷头可实现多角度调整,高速开启关闭,液体灌装过程更稳定、高效。

Industries

多个伺服电机控制的供袋系统,无论是任何型式、材质的包装,均可在全伺服供袋系统上实现高速生产。

真空系统自带过滤装置,可快速实现清洁和更换,设备维护更加简单。

可配置高速拉链打开装置,即使是拉链袋也能实现高速包装。

密封式灌装配合仿形吸尘,使得物料灌装过程中的粉尘控制做到极致。

Industries

The level and height of the packaging bag can be detected online, so that the quality and appearance of the final product can be more guaranteed.

High speed zipper opening device is an optional and realize high-speed packaging even for zippered bags.

The quick connection technology of the funnel makes the funnel replacement faster and easier.

在灌装物料的过程中,通过袋子底部的振动使得物料更均匀灌入

Detailed parameters

-

- Filling Materials

- Solid, Fluid, Solid+Fluid, Powder

-

- Min. Pouch Size(Width x Height x Bottom)(mm)

- 170 x 300 x (25 x 2)

-

- Max. Pouch Size(Width x Height x Bottom)(mm)

- 430 x 1,000 x (75 x 2)

-

- Speed Range(pouch/min.)

- 10-40(Actual speed depends on the properties of specific filling materials.)

-

- Voltage

- AC380V

-

- Frequency(Hertz)

- 50HZ/60HZ

-

- Power

- 8kW

-

- Air Consumption(m³/min)

- 0.6-1.5

-

- Noise Index

- <80dB

-

- Machine Dimension(L x W x H)(mm)

- 5,212 x 2,000 x 2,550

-

- Machine Max Dimension(L x W x H)(mm)

- 5,304 x 4,876 x 3,800

More equipment

-

-

-

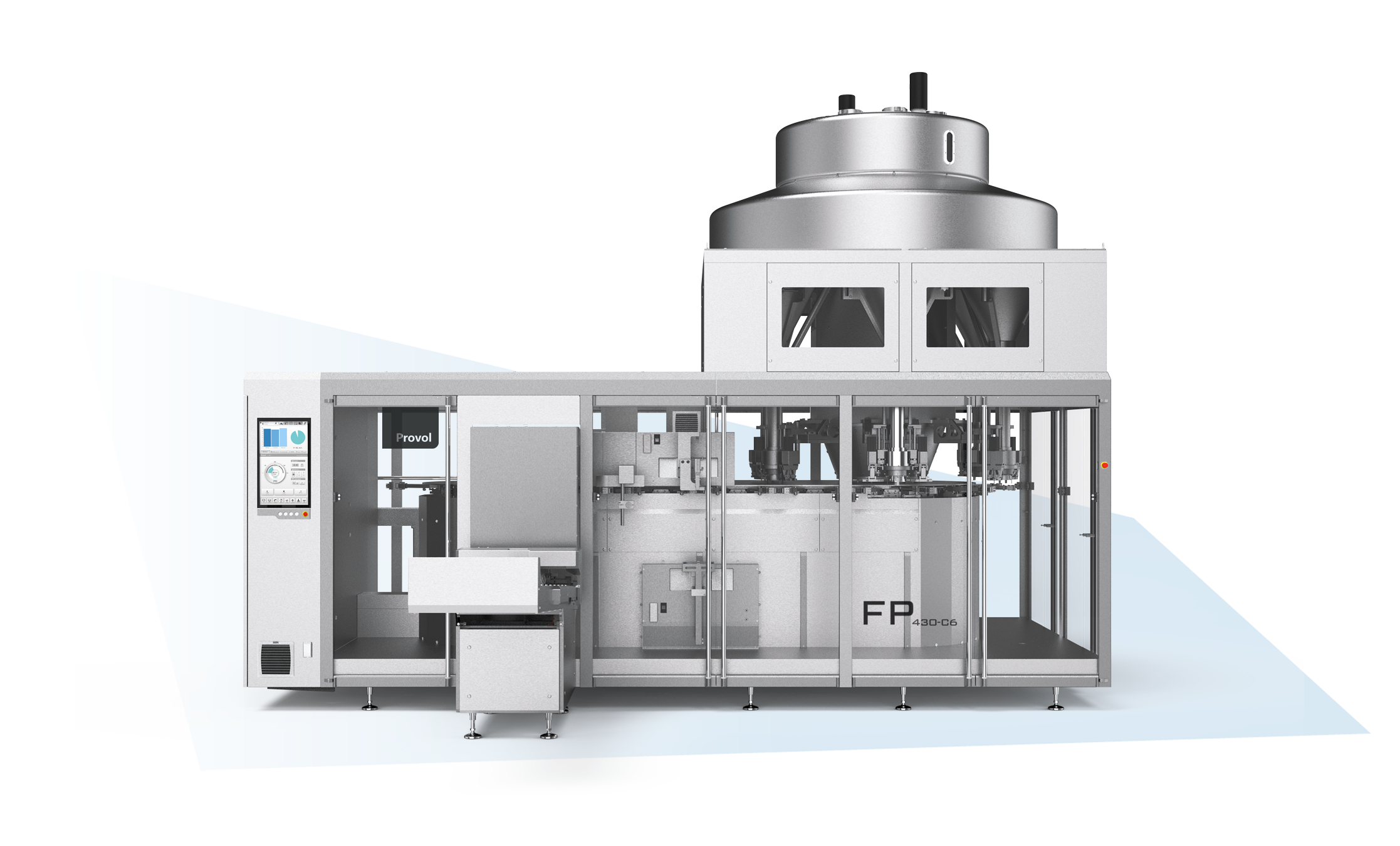

FP-430-C6

The speed range of flexible high-speed packaging machine FP430-C6 is 20-60 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×600(H)mm.

The machine FP430-C6 has complete functions and good performance for continuous and stable production output.

-

-

-

-

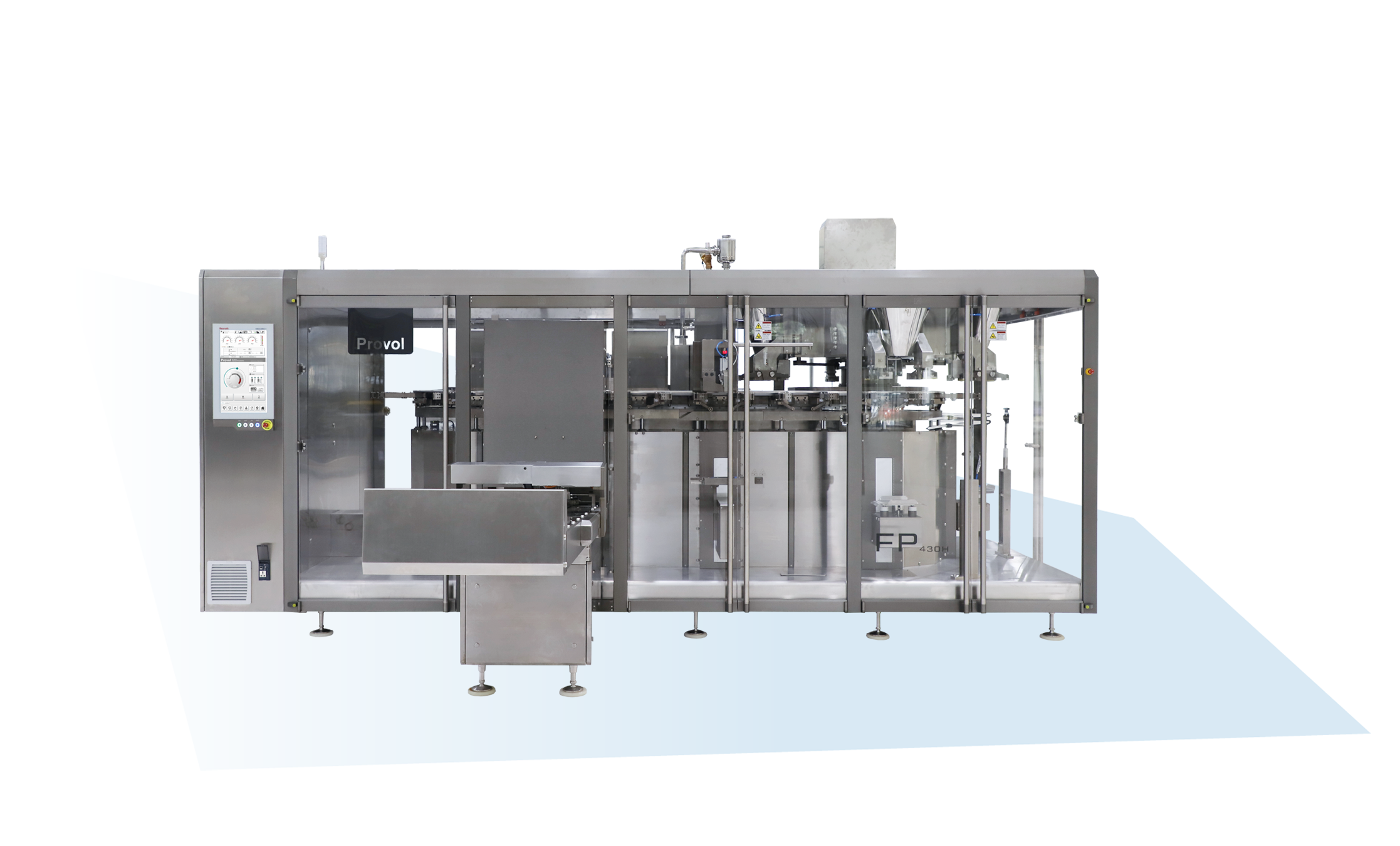

FP-430H-I1

The speed range of flexible high-speed packaging machine FP430H-I1 is 20-50 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×800(H)mm.

Run much faster, more stable and no time limited to fill the products due to the continuous flowing hoppers on the machine.

-