-

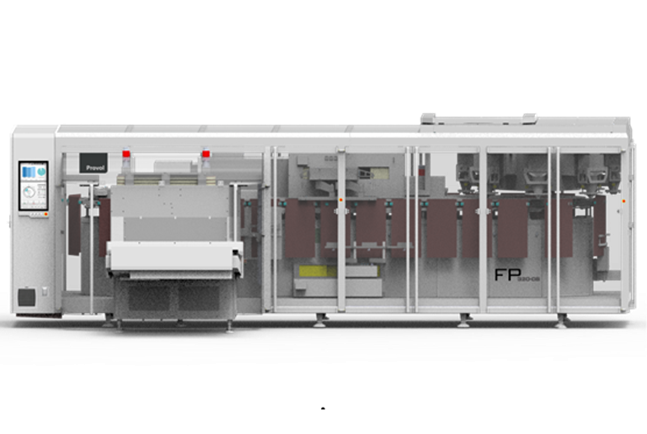

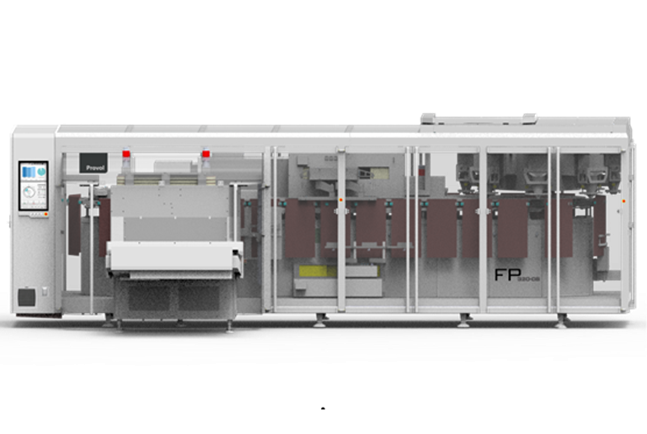

FP3-320-C8

Excellent performance of extreme speed and flexibility

- Excellent speed-continuous running mode to ensure the high speed of the machine, easy to realize the high-speed output of 100ppm.

- Flexible changeover-Quick changeover by clicking one button on the HMI, covering a wide range of sizes. Simplify the operation process and improve production efficiency.

- Stable performance- Lower energy consumption, lower noise, long-term stable operation.

-

Characteristics

- Production Efficiency

Continuous and stable production output

The multiple filling station, which is 4.5 times longer than the filling time on the traditional machine.

-

- Quick changeover

Meet wide format range

Recipes design for production changeover, all of the parts for each changeover are clear at a glance, and changeover time is recorded in real time, which provides any possibility to continuously optimize the efficiency of production changeover.

-

- Product quality

System closed-loop quality control

The online weighing module, bag loading detection, bag height detection, coding detection and other sets of detection will accurately monitor OEE of the whole machine in real time, and display the data on HMI, which accurately control product quality.

-

- Health and Safety

Food grade hygiene standards

The F series packaging machine is designed according to Provol hygienic design standard. High sealing feature of the machine driving part, no hygienic dead corner for the exposed mechanical assemblies, and the air tube wiring is hidden into the structure, that is easy to clean.

For some parts that need to be removed to clean and replace such as the teflon cloth of sealing jaws, conveyor belt, etc., which are quickly cleaned and no tools needed. -

- Easy to operate

Full Automation, Easier Operation.

Multiple detection feedback functions such as bag loading, bag loading height and coding detection can more accurately monitor the OEE efficiency of the overall machine, and display it on the HMI in real time. The HMI adopts a new UI design concept, which can support multi-users browsing, display statistical production data and machine operating status.

-

- Space usage

Flexible space performance

Smaller footprint, more reserved worksations.

The multiple continuous filling stations greatly improve the space efficiency of the overall machine. -

Industries

Industries

The bag feeding system controlled by multiple servo motors can realize high-speed production regardless of packaging type and material.

The level and height of the packaging bag can be detected online, so that the quality and appearance of the final product can be more guaranteed.

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

Bag-Bottom vibrating makes the filling process more smooth and the materials more even.

Industries

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

The level and height of the packaging bag can be detected online, so that the quality and appearance of the final product can be more guaranteed.

Bag bottom opening/keep opening can be configured, the height can be adjusted automatically according to the bag size.

It can be matched with laser, inkjet, heat transfer and other types of coding, and can be matched with quick adjusted mounting brackets.

Industries

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

The machine reduce redundant plane and avoids exposed bolts and gas pipes, which is easier to clean.

Blow the bag to enlarge the space inside the bag. Integrated real-time feedback for bag opening detection, only when the bag is opening, the filling function can be triggered.

High speed zipper opening device is an optional and realize high-speed packaging even for zippered bags.

Industries

Bag-Bottom vibrating makes the filling process more smooth and the materials more even.

The continuous following hopper system increases the filling time by more than 4 times! The product can achieve higher speed even on a high FAR.

The level and height of the packaging bag can be detected online, so that the quality and appearance of the final product can be more guaranteed.

The bag feeding system controlled by multiple servo motors can realize high-speed production regardless of packaging type and material.

Detailed parameters

-

- Filling Materials

- Solid, Fluid, Solid+Fluid, Powder

-

- Min. Pouch Size(Width x Height x Bottom)(mm)

- 130 x 200 x (25 x 2)

-

- Max. Pouch Size(Width x Height x Bottom)(mm)

- 320 x 600 x (75 x 2)

-

- Speed Range(pouch/min.)

- 60-100(Actual speed depends on the properties of specific filling materials.)

-

- Voltage

- AC380V

-

- Frequency(Hertz)

- 50HZ/60HZ

-

- Power

- 15kW

-

- Air Consumption (m³/min)

- 0.6-1.5m³/min

-

- Noise Index

- <80dB

-

- Machine Dimension(L x W x H) (mm)

- 12,688 x 2,053 x 2,356

-

- Machine Max Dimension(L x W x H) (mm)

- 12,688 x 2,053 x 2,356

More equipment

-

-

-

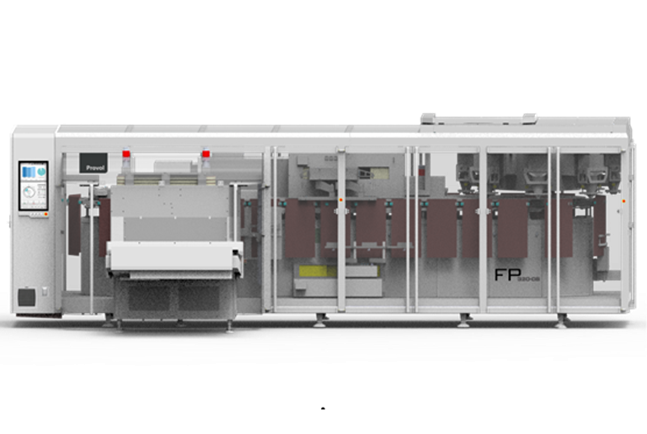

FF-210-C8

The speed range of flexible high-speed packaging machine FF210-C8 is 100-160 ppm.

The pouch sizes range: min size as 100(W)×140(H)mm, max size as 205(W)×320(H)mm.

FF210-C8 runs continuously and stably for a long time, the fastest output can be up to 9600 pouches per hour.

Large output, on-line pouch manufacture from roll film, the value can be calculated.

-

-

-

-

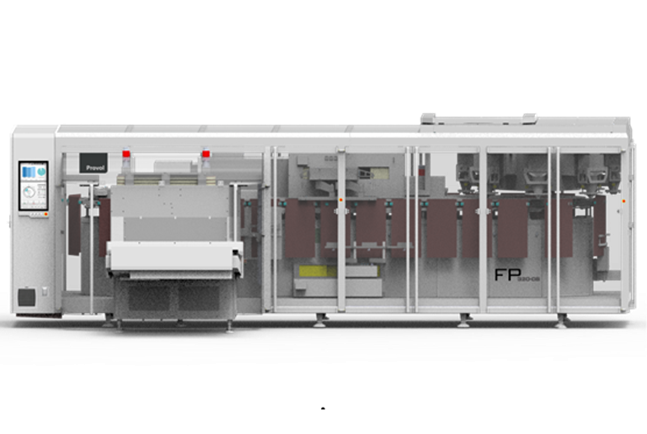

FP-430L-I1

The speed range of flexible high-speed packaging machine FP430L-I1 is 10-40 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×1000(H)mm.

Wide format range of the machine FP430L-I1 is from min 165mm to max 430mm, the max bag height can be up to 1 meter.

-