-

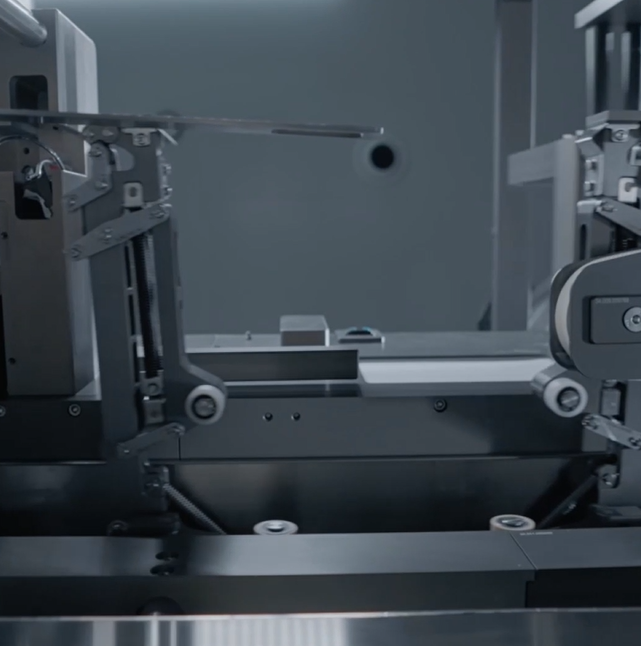

FF-210-I2

Automation,Free change

- Packaging automation is the process of packing a product without human intervention. Over the years, automated packaging systems have moved from single machines that automate one step in the packaging process to machines that now seamlessly integrate all steps into the entire packaging process.

- Stable performance - continuous motion mode, lower noise.

- High-speed output -9600 pouches per hour at the fastest.

- Full servo drive, greatly reduce the demand for the operators, only one operator is needed.

- Increased productivity

- Consistency of packaging

- Reduced losses and savings in transport and storage costs

- Reduced labour costs

- Reduced carbon footprint

- Stand-alone and end-to-end systems that make your production faster, smarter and more cost effective

-

Characteristics

- Easy to operate

Easy to operate, freindly interface

Multiple detection feedback functions such as bag loading, bag loading height and coding detection can more accurately monitor the OEE efficiency of the overall machine, and display it on the HMI in real time.

The HMI adopts a new UI design concept, which can support multi-users browsing, display statistical production data and machine operating status. -

- Continuous flowing filling

Stable operation for a long time

Flowing filling module, high volume ratio is no longer as bottleneck. The filling time is longer than 3 times compared with the traditional machine.

-

- Quick changeover

Free changeover for multiple SKU

Recipes design for production changeover, all of the parts for each changeover are clear at a glance, and changeover time is recorded in real time, which provides any possibility to continuously optimize the efficiency of production changeover.

All of the changeover parts adopt the quick disassembly structure, which can custome design all of the neccessary accessories according to the customers various SKU production. -

- Cost saving

Less film loss

Packaging materials reduction due to the accurate die cutting.

-

- Space usage

Flexible space performance

Smaller footprint, more reserved worksations.

The multiple continuous filling stations greatly improve the space efficiency of the overall machine. -

- Product quality

Strict control of product quality

The online weighing module, bag loading detection, bag height detection, coding detection and other sets of detection will accurately monitor OEE of the whole machine in real time, and display the data on HMI, which accurately control product quality.

-

- Health and Safety

Food grade hygiene standards

The F series packaging machine is designed according to Provol hygienic design standard. High sealing feature of the machine driving part, no hygienic dead corner for the exposed mechanical assemblies, and the air tube wiring is hidden into the structure.

-

Industries

Industries service

The hopper can support at four corner of the bag.

The packaging can be formed through die-cut function, which can meet the customized design.

The punching module is an optional function to meet all the needs of European holes,easy tear holes,etc.

The machine can be integrated with online zipper function without speed loss.

The automatic reel splicing system allows you tu change running web rolls without stopping production.

Industries service

The camera detection function can be configured and detect printing quality, content, QR code, barcode and other contents online.

It can be compatible with multihead weigher, linear weigher and other weighing equipment. It can be quickly docked, easily disassembled and cleaned.

Pre-made pouch supply module enables you to produce both pre-made pouch and film forming on a single machine.

The cap adding module is an optional function and can be easy to manipulate.

Various bag types can be forming and quickly switched.

Industries service

The de-air system is effcient through vaccum and mechanical extrusion,which can ensures the transportation and safety of the product.

Fixed or follow-up filling mode can be configured,so that the machine can achieve higher floor area ratio and higher speed for the product.

Serve bag vibrating function makes the filling process more smooth and the materials more even.

Built in cyclone separator, which can easily realize waste recycling and separation.

Various bag types can be forming and quickly switched.

The machine can be integrated with online zipper function without speed loss.

Industries service

The cap adding module is an optional function and can be easy to manipulate.

The packaging can be formed through die-cut function, which can meet the customized design.

The punching module is an optional function to meet all the needs of European holes,easy tear holes,etc.

The automatic reel splicing system allows you tu change running web rolls without stopping production.

Pre-made pouch supply module enables you to produce both pre-made pouch and film forming on a single machine.

Detailed parameters

-

- Filling Materials

- Solid, Fluid, Solid+Fluid, Powder

-

- Min. Pouch Size(Width x Height x Bottom)(mm)

- 100 x 140 x (25 x 2)

-

- Max. Pouch Size(Width x Height x Bottom)(mm)

- 205 X 320 X (50 X 2)

-

- Speed Range(pouch/min.)

- 80-120(Actual speed depends on the properties of specific filling materials.)

-

- Voltage

- AC380V

-

- Frequency(Hertz)

- 50HZ/60HZ

-

- Power

- 15KW

-

- Air Consumption (m³/min)

- 0.6-1.5

-

- Noise Index

- <80dB

-

- Machine Dimension(L x W x H) (mm)

- 11,188 X 1,767 X 2,150

-

- Machine Max Dimension(L x W x H) (mm)

- 11,254 X 2,010 X 2,150

More equipment

-

-

-

FF-210-C8

The speed range of flexible high-speed packaging machine FF210-C8 is 100-160 ppm.

The pouch sizes range: min size as 100(W)×140(H)mm, max size as 205(W)×320(H)mm.

FF210-C8 runs continuously and stably for a long time, the fastest output can be up to 9600 pouches per hour.

Large output, on-line pouch manufacture from roll film, the value can be calculated.

-

-

-

-

FP-210-I2

The speed range of flexible high-speed packaging machine FP210-I2 is 80-120 ppm.

The pouch sizes range: min size as 100(W)×140(H)mm, max size as 210(W)×340(H)mm.

Qiuck changeover within 10S, only one-key on HMI, Demands meet various factory application.

-