Flexibility - For More Possibilities

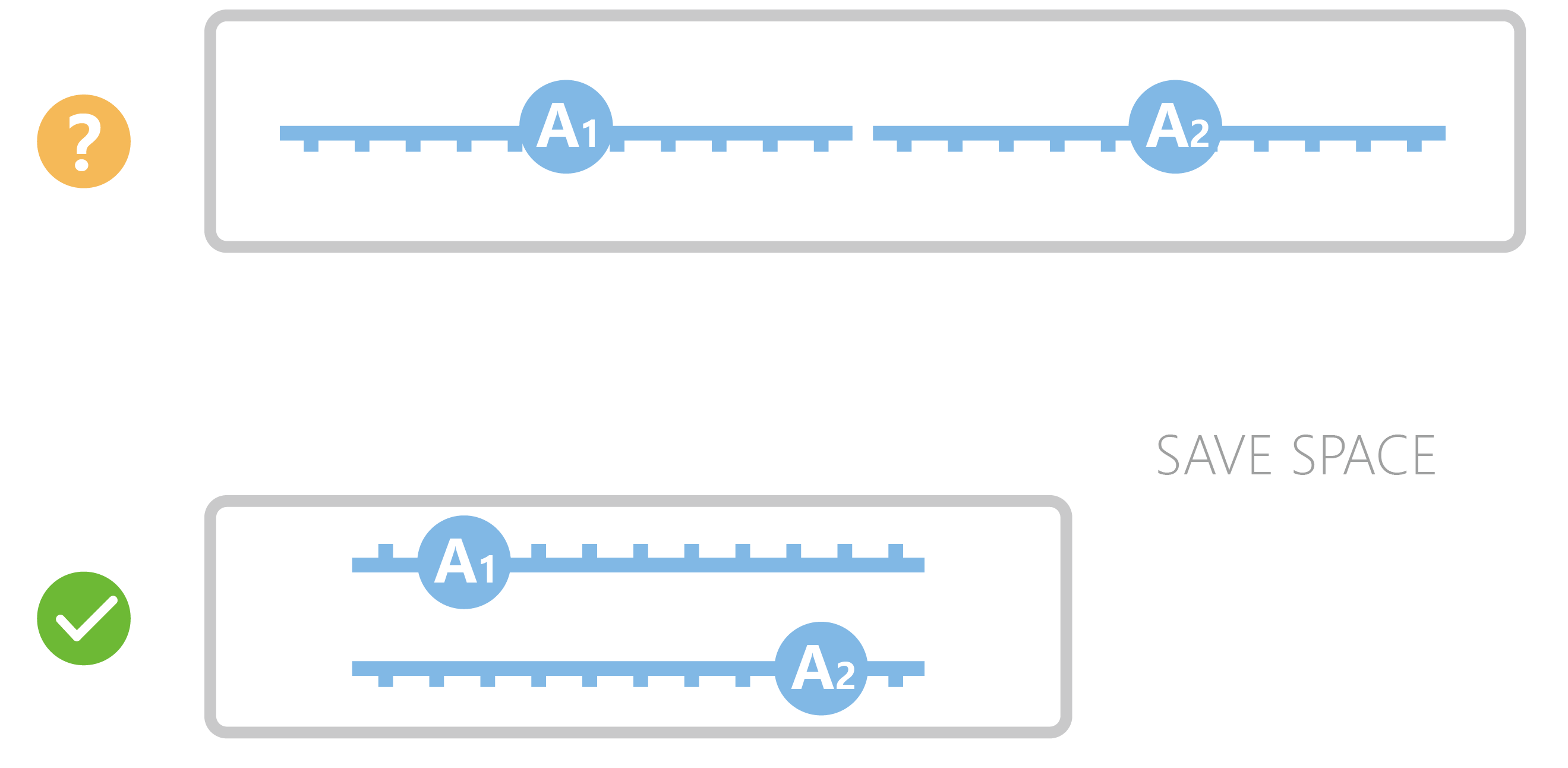

F-Series machine provides more flexible packaging machine solution.

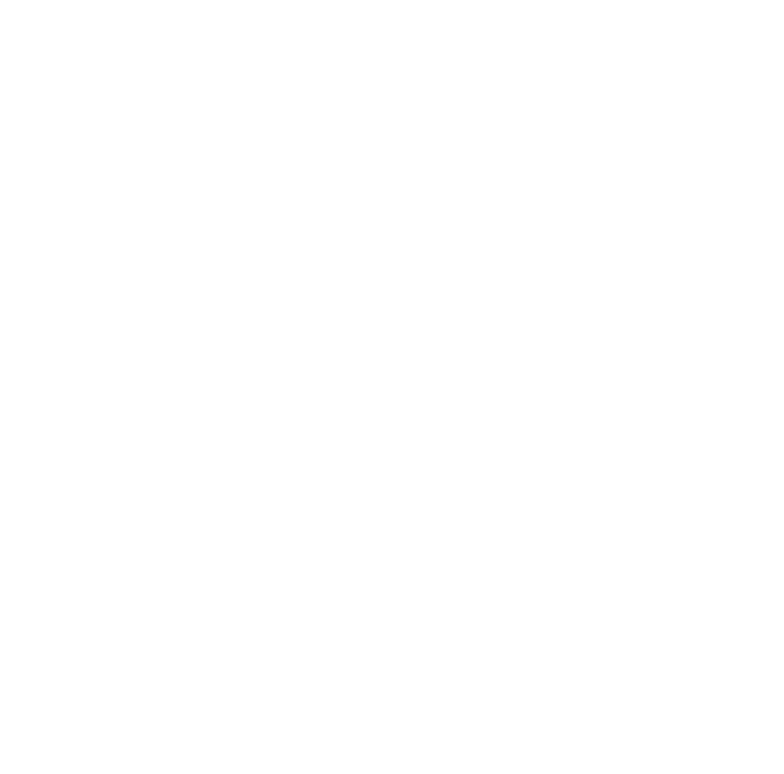

- ·Shared-Chain-Structure with Double Operation Sides

- ·New HMI 4.0

- ·One-key Changeover

- ·Open and Hygienic Design

More equipment

-

-

-

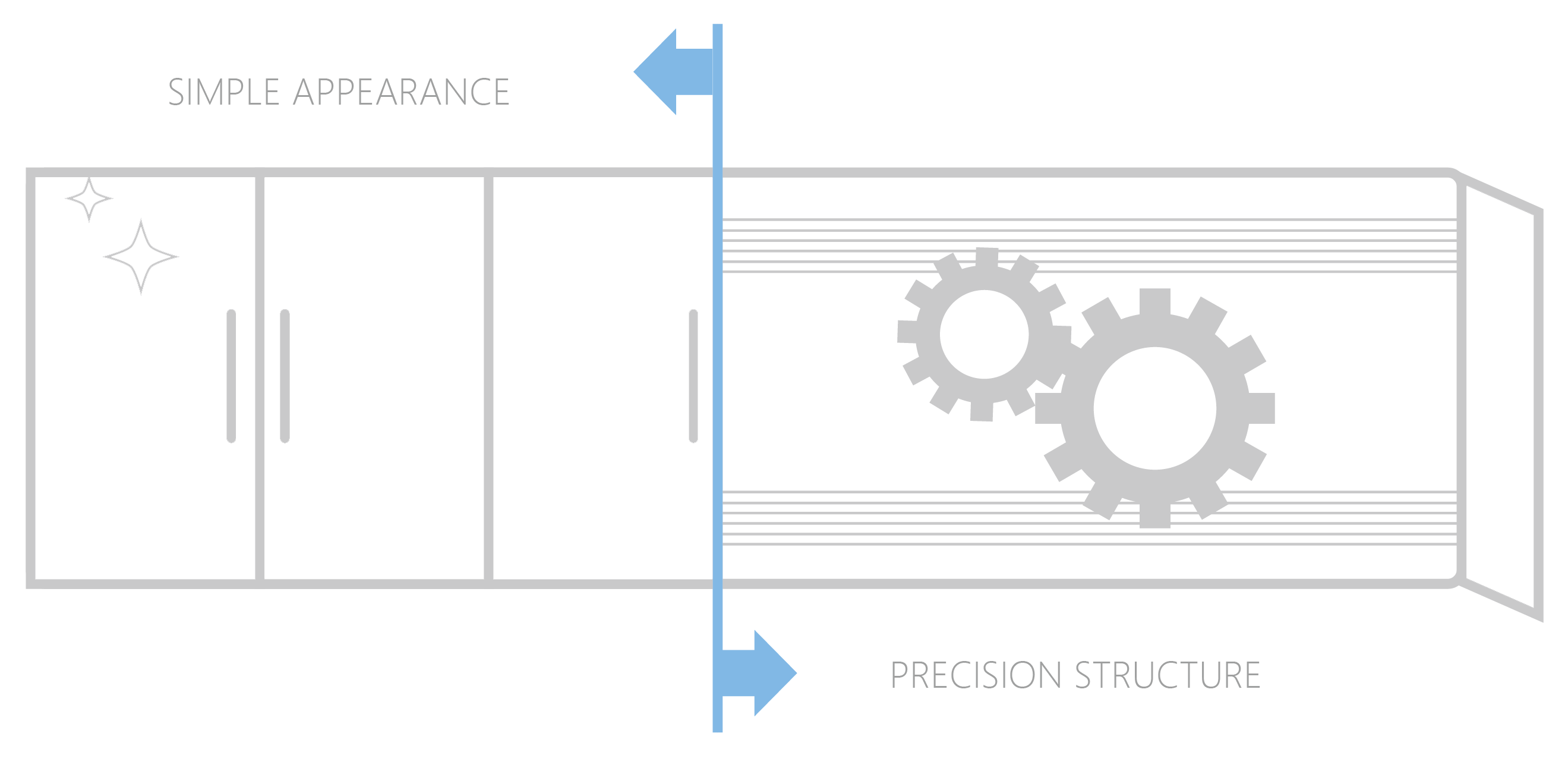

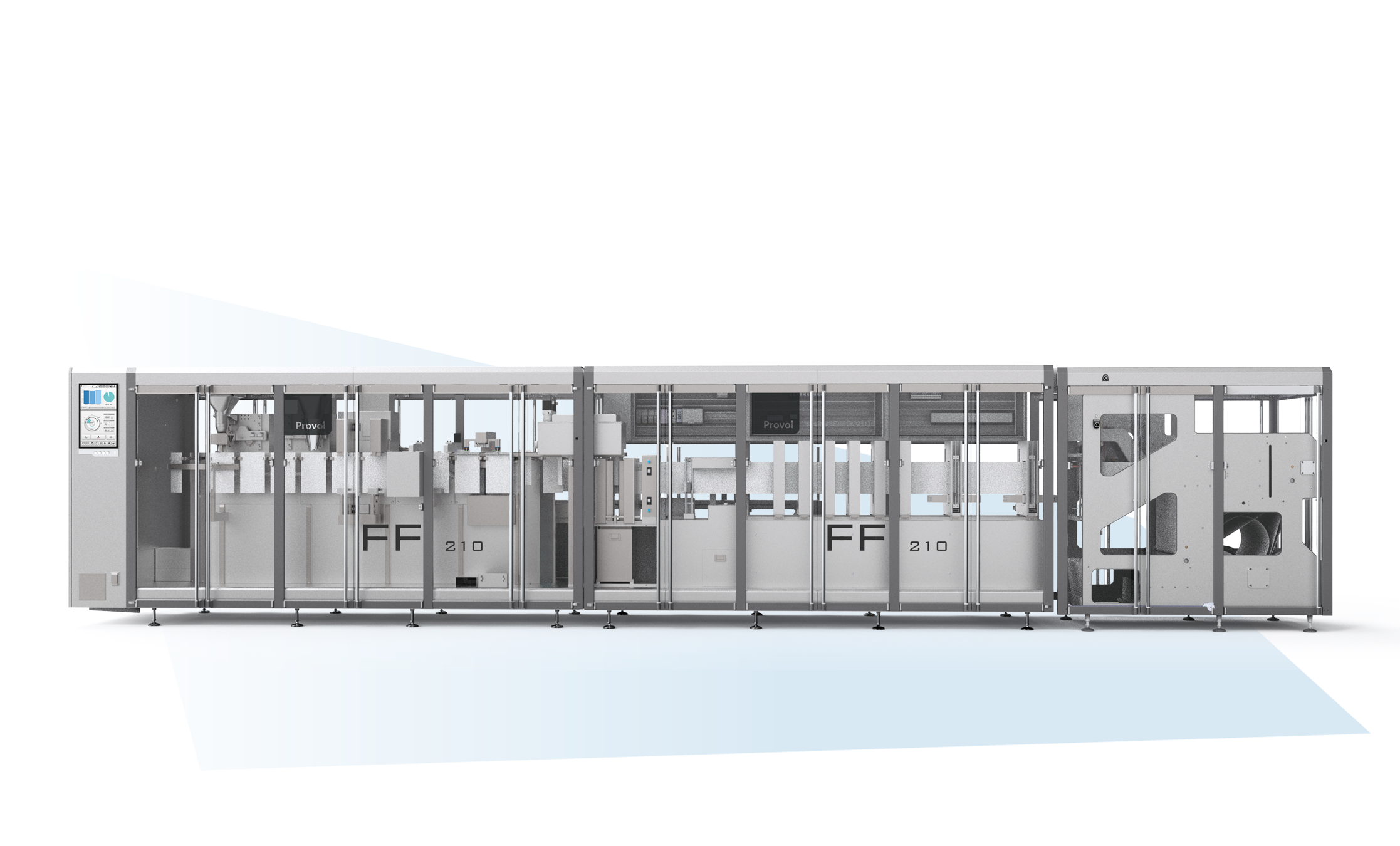

FF3-210-C8-3C

The speed range of flexible high-speed packaging machine FF3-210-C8-3C is 150-180 ppm.

The pouch sizes range: min. size as 100(W)×140(H)mm, max. size as 205(W)×320(H)mm.

Overcoming the pain points of the industry from production efficiency, labor cost, material loss, and quality assurance. Whether mass production or multi-specification flexible orders, it can provide one-step packaging solutions for food and beverage, condiments, pet food, and other industries.

-

-

-

-

FF2-320-C8

The speed range of flexible high-speed packaging machine FF2-320-C8 is 80-120 ppm.

The pouch sizes range: min. size as 130(W)×200(H)mm, max. size as 320(W)×320(H)mm.

It can still operate at high speed and stability even with large-sized packaging, it supports quick changeover and automatic adjustment of multiple SKUs, reducing the costs of manual work and changeover, while achieving stable output of both efficiency and quality.

-

-

-

-

FF-210-I2

The speed range of flexible high-speed packaging machine FF210-I2 is 80-120 ppm The pouch sizes range: min size as 100(W)×140(H)mm, max size as 205(W)×320(H)mm.

FF210-I2 runs continuously and stably for a long time, the fastest output can be up to 9000-18000 pouches per hour.

-

-

-

-

FF-210-C8

The speed range of flexible high-speed packaging machine FF210-C8 is 100-160 ppm.

The pouch sizes range: min size as 100(W)×140(H)mm, max size as 205(W)×320(H)mm.

FF210-C8 runs continuously and stably for a long time, the fastest output can be up to 9600 pouches per hour.

Large output, on-line pouch manufacture from roll film, the value can be calculated.

-

-

-

-

FP-210-I2

The speed range of flexible high-speed packaging machine FP210-I2 is 80-120 ppm.

The pouch sizes range: min size as 100(W)×140(H)mm, max size as 210(W)×340(H)mm.

Qiuck changeover within 10S, only one-key on HMI, Demands meet various factory application.

-

-

-

-

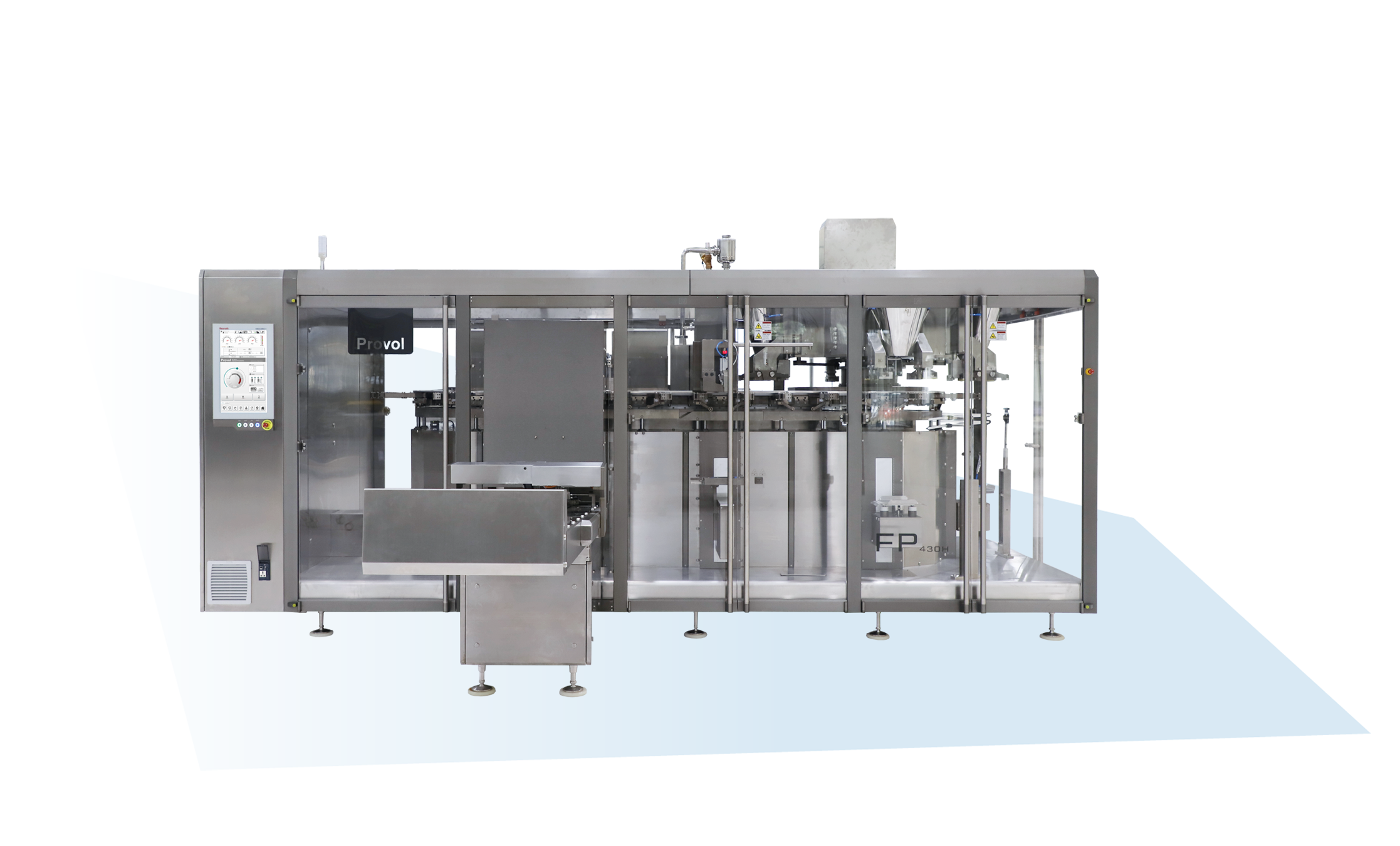

FP-430H-I1

The speed range of flexible high-speed packaging machine FP430H-I1 is 20-50 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×800(H)mm.

Run much faster, more stable and no time limited to fill the products due to the continuous flowing hoppers on the machine.

-

-

-

-

FP-430L-I1

The speed range of flexible high-speed packaging machine FP430L-I1 is 10-40 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×1000(H)mm.

Wide format range of the machine FP430L-I1 is from min 165mm to max 430mm, the max bag height can be up to 1 meter.

-

-

-

-

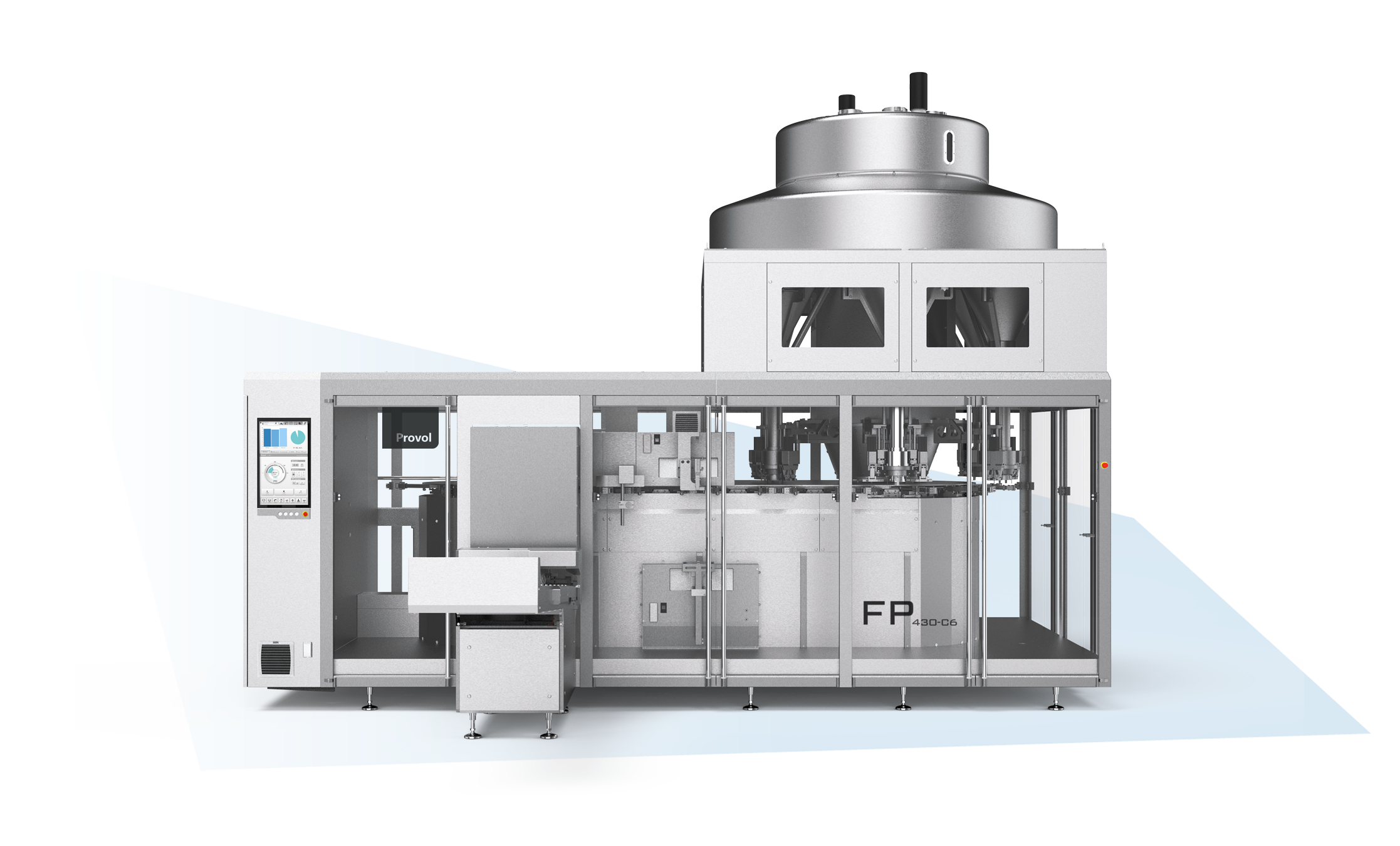

FP-430-C6

The speed range of flexible high-speed packaging machine FP430-C6 is 20-60 bpm.

The pouch sizes range: min size as 170(W)×300(H)mm, max size as 430(W)×600(H)mm.

The machine FP430-C6 has complete functions and good performance for continuous and stable production output.

-

-

-

-

FP3-320-C8

The speed range of flexible high-speed packaging machine FP3-320-C8 is 60-100 ppm.

The pouch sizes range: min size as 130(W)×200(H)mm, max size as 320(W)×600(H)mm.

Continuous operation, high-speed and more stable;

large-span automatic adjustment to meet more possibilities

-