What’s FFS Packaging?

What’s FFS Packaging?

Flexible packaging involves the use of non-rigid materials to package products, which offers more affordable and customizable options. Despite being a relatively new method in the packaging market, it has become increasingly popular due to its efficiency and cost-effectiveness. Flexible packaging can easily change shape when filled or in use, and can be made from various materials like paper, plastic, film, aluminum foil, or combinations thereof. Examples of flexible packaging include bags, pouches, liners, wraps, rollstock, and other similar products. This type of packaging is particularly beneficial for industries that require versatile packaging, such as food and beverage, personal care, and pharmaceutical industries.

What’s FFS packaging?

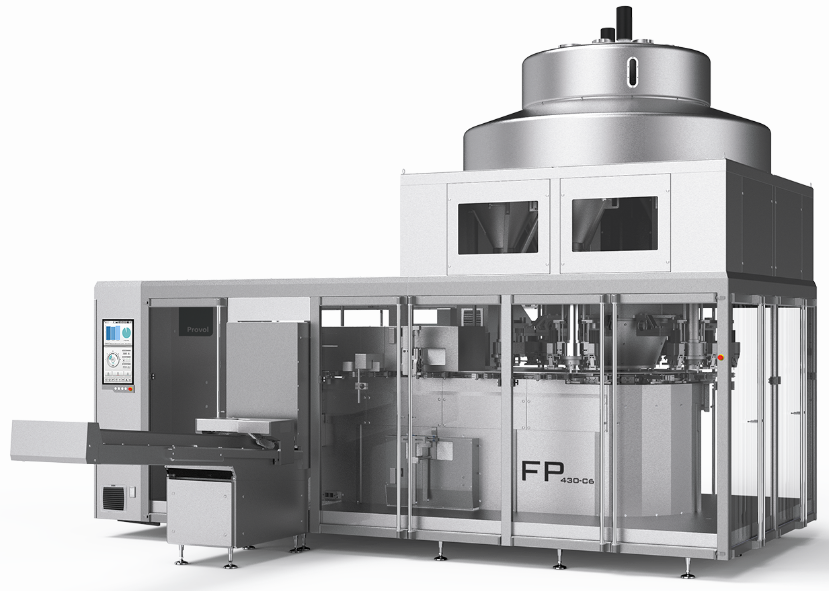

An FFS machine constructs plastic bags and stand-up pouches out of a flat roll of film, while simultaneously filling and sealing the bags with solid or liquid product. The objective of an FFS machine is to reduce the contamination during manufacturing by forming, filling, and sealing the product in a sterile chamber inside the machine. This protects the product from any personnel interaction or bacteria in the outside environment. Provol horizontal form fill and sealing (FFS) solutions include thermoforming packaging for various food and medical products. FFS packaged foods include dairy products, condiments, meats, juices and more. Non-food medical products can be anything from ointments to syringes and other medical supplies that require careful packaging and high sanitation.

Types of ffs machine:

FFS Packaging

There are two types of FFS machines that offer flexible packaging solutions; a horizontal machine (HFFS) and a vertical machine (VFFS). The difference between these machines involves the way the products are dispensed into the packages.

HFFS Machine

The horizontal FFS machine creates the top and bottom seals for a package from the film sheet by applying heat and pressure. Operation is intermittent in an HFFS machine where the plastic film is drawn off a supply reel by a pair of rollers. The reel passes through a folding plough which folds it in half.

Advantages of FFS Technology

High speed and consistent packing rate

Economical as the bags made are less expensive than pre-made bags

Provides increased production rate so you can reduce number of shifts

Easy and quick to clean-out between production batches

Online film printing provides readable bar code and product info

Fewer moving parts – especially in VFFS

Disadvantages of FFS Technology

Cannot handle paper

Not economical for short production runs

Cannot handle multi-ply packaging materials

Cannot remove trapped air quickly

Not economical for low density, aerated powders such as wheat flour, talcum powder, whey powder at medium speeds

Applications of FFS packaging machines

The applications of FFS packaging machines are endless. Almost any product that can be packed and marketed in flexible pouches can be packaged by such machines. FFS machines can be used to pack a whole gamut of food, pharm and other

products ranging from:

grains (such as rice, pulses, sugar) to granulates (such as detergent, fertilizers)

snacks (such as chips, dry fruits, namkeen) to ready-to-eat foods

bulk goods (such as nuts and cookies to bolts and screws)

powders (such as spice powders, milk powder, ground coffee, nutraceuticals)

liquids (such as water, milk, juice, liquor) to viscous (such as edible oil, ghee, ketchup, mayonnaise, salad dressing, bath gel)

Pouch/Bag formats with FFS technology

Versatility to form and fill a variety of container formats is a strong point of FFS technology. The options include:

Pillow pouch

3 side seal and 4 side seal pouches

Gusset pouch

Pentaseal pouch

Sachet & stickpack

Standup pouch (with zipper/spout/euro slot/handle, etc.)

Doypack

Thermoform trays

Cartons

Hffs Machine Supplies

ProvolF-Series flexible packaging machine

·Shared-Chain-Structure with Double Operation Sides·New HMI 4.0·One-key Changeover·Open and Hygienic Design

You can quickly change production to a different product format by touching the control screen or other related mobile control terminal, then the machine will automatically adjust the distance of clamps, the height of sealing blocks,and so on.The fastest changeover can be achieved within 10 seconds, which save the time to the greatest extent and improve the machine OEE (Overall Equipment Efficiency). The flexible packaging machine manages all bag types and sizes, allowing you to use any packaging for your products.

During the process,all the operation processes are controlled and visible at the mobile terminal.

Flexible Packaging Machine Expert|Provol

As an industry-leading innovative packaging technology company, Provol offers professional automatic packaging machines, customized production line design, system integration as well as one-stop packaging solutions to high-end customers in different industries worldwide.

With over 20-year industry experiences, Provol has gained trust and reputation by offering flexible packaging machine and integrated solutions to customers in food, condiments, health-care products, household detergent products, pet food, pharmaceuticals and other industries.

For more information about automatic packaging information and other applications, welcome to contact us, please visit our website at http://www.provol.com/en/ We will be happy to help you out!