Provol Provided Packaging Solution Successfully to the New Production Line of Totole, a Nestle Group Subsidiary in China

Bag Type Upgrade, Better Performance

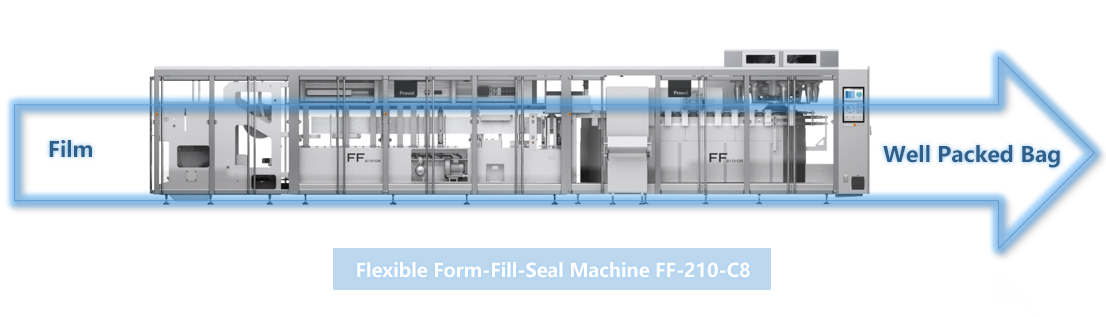

To well manufacture doybag with corner spout and fill up to 100bags/min.

Unlike previous bag types, Totole requires the use of a doybag with a corner spout, which poses new challenges to the technology and output requirements. In order to meet the customer's demands, Provol packaging machines have been further developed and upgraded. The new and improved machine incorporates more stringent heat-sealing technology, an expanded double-station capping module, and an innovative 8-station continuous follow-up filling system, which enables it to achieve a production rate of 100 bags per minute. The machine maintains high-quality packaging standards while significantly increasing production capacity by four times. The machine's outstanding production speed and stable performance, coupled with the professional technical support provided by Provol technical and service team, have garnered customer recognition and satisfaction.

Faster, More Stable, More Flexible

High Overall Equipment Effectiveness

As the market share of Totole's new products has grown, and stricter standards have been imposed on packaging quality, Provol's high-speed and flexible form-fill-seal packaging machine FF-210-C8 has emerged as the optimal choice due to its exceptional performance.

Trust comes from quality

Understand the needs of customers, and provide the best solution for customers.

In order to bring a better experience to Totole, Provol technical team has strict control and precise requirements for the project, and delivered convincing results to customers during the first test. While meeting the performance, the driving part of the whole machine also has high sealing performance, the filling module is isolated from other modules, and is equipped with quick assembly tooling for collecting and discharging materials, which is convenient for cleaning. The exposed mechanical mechanism has no hygienic dead angle design, which reduces the burden of machine cleaning and maintenance, thereby prolonging the service life of the equipment. At the same time, Provol after-sales technical team provides customers with one-stop services from installation and commissioning to after-sales maintenance, and its professional service capabilities provide customers with a strong guarantee.

For Provol, the cooperation with Totole again is a new challenge. In-depth research, development and adjustments have been made in terms of technology, process and equipment. The strict requirements of the product quality and consumer experience from Totole are fully understood by Provol team. As a leading global provider of packaging solutions, Provol continuously meet the different needs of customers in products, brand image, and the market by providing custom design packaging solutions, and support customers to enhance their competitiveness, and create more value.