A Comparison Between Flexible High-Speed Packaging Machines and Traditional Machinery

Introduction

In today's rapidly evolving manufacturing landscape, the packaging industry plays a crucial role in ensuring products reach consumers safely and efficiently. To meet the demands of modern production, there has been a significant shift towards flexible high-speed packaging machines. This article will explore the key differences between these advanced machines and traditional packaging machinery, shedding light on the advantages of adopting flexible high-speed packaging technology.

Traditional Packaging Machinery

Traditional packaging machinery has been the cornerstone of the industry for decades. These machines are typically designed for specific packaging tasks, such as filling, sealing, and labeling, and are optimized for high-volume production of a single product type. They offer stability, reliability, and ease of use, making them a trusted choice for many manufacturers.

However, traditional machinery has limitations when it comes to versatility and adaptability. Switching between different product sizes and packaging formats can be time-consuming and require significant manual adjustments. This inflexibility can hinder manufacturers' ability to respond quickly to changing market demands and consumer preferences.

Flexible High-Speed Packaging Machines

Flexible high-speed packaging machines, on the other hand, represent the cutting edge of packaging technology. These machines are designed with modularity and adaptability in mind. They can easily accommodate a wide range of product sizes, packaging formats, and labeling requirements without the need for extensive reconfiguration.

One of the key advantages of flexible high-speed packaging machines is their ability to significantly reduce downtime during changeovers. Manufacturers can quickly switch between different products and packaging configurations, allowing them to respond promptly to market trends and customer demands. This increased flexibility enhances operational efficiency and reduces production costs.

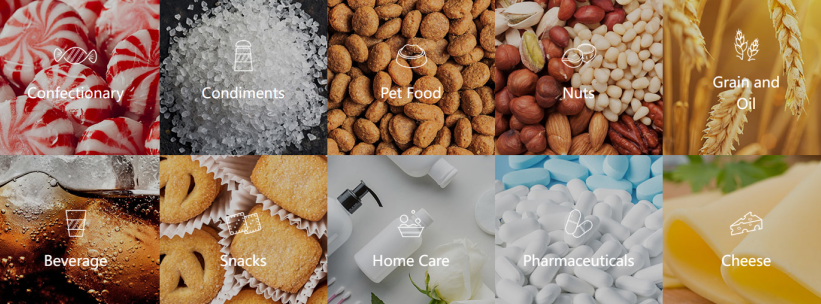

Furthermore, these machines often incorporate advanced automation and control systems, improving precision and consistency in the packaging process. They can handle various packaging materials and types, including pouches, bottles, cartons, and more. This versatility makes them ideal for industries with diverse product lines.

Conclusion

In the ever-evolving world of manufacturing and packaging, flexible high-speed packaging machines have emerged as a game-changer. While traditional packaging machinery offers stability and reliability, the flexibility and adaptability of advanced machines make them a compelling choice for manufacturers looking to stay competitive and responsive to market dynamics.

Ultimately, the choice between traditional packaging machinery and flexible high-speed packaging machines depends on the specific needs and goals of a manufacturer. However, in an era of rapid change and evolving consumer preferences, the ability to adapt quickly and efficiently is a valuable asset that flexible high-speed packaging machines bring to the table.