Custom Packaging Machine | Provol

Category:Industry Market

Publication Time:2023-01-09

Author:RN-Z

Page view:

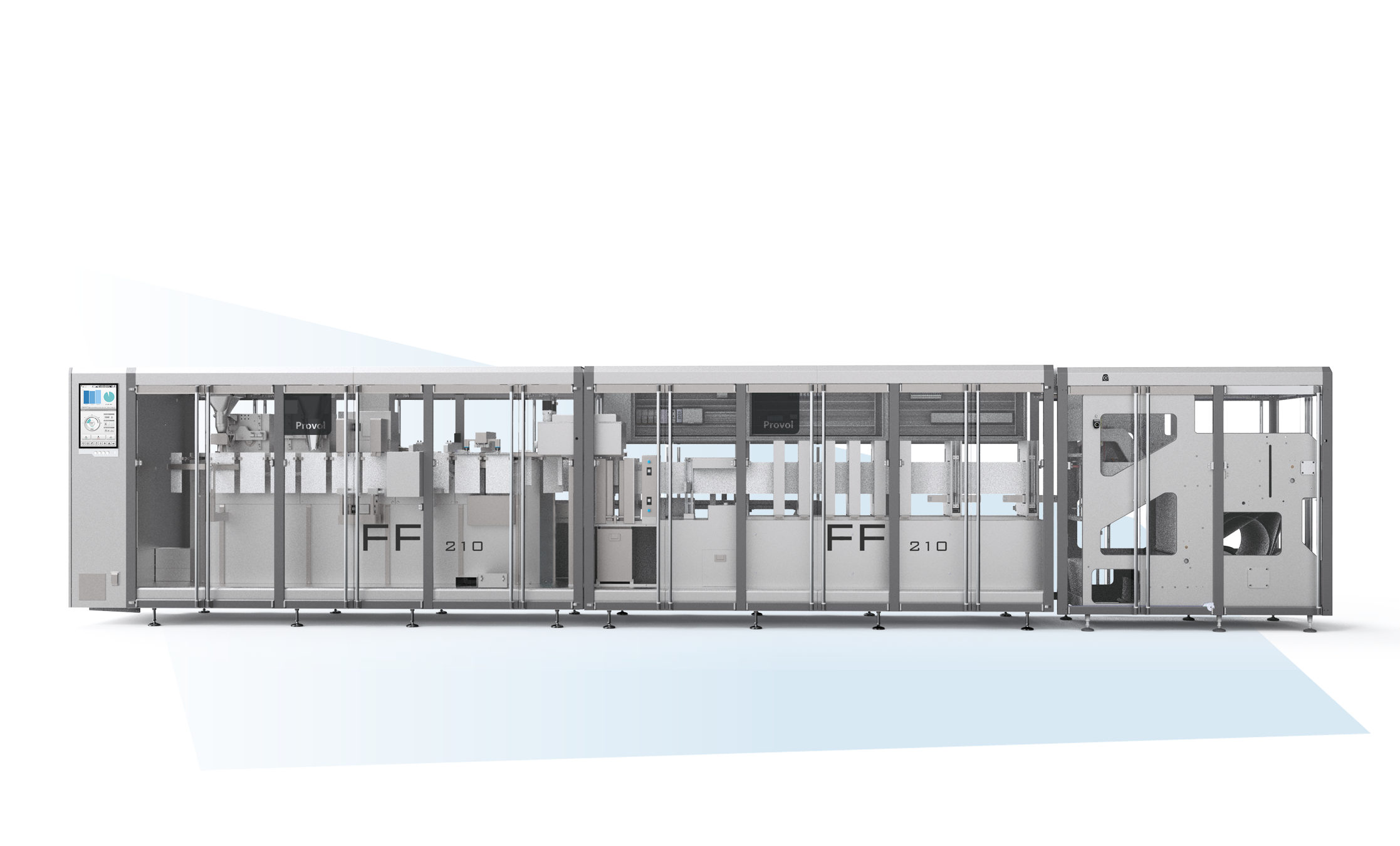

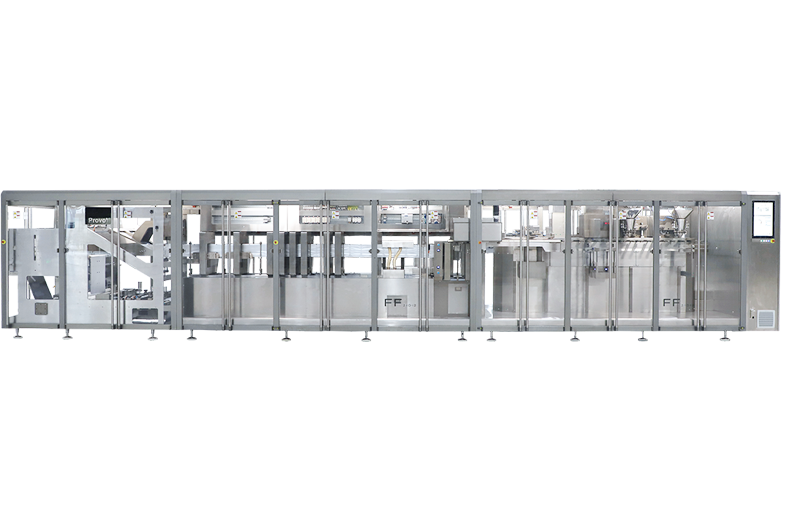

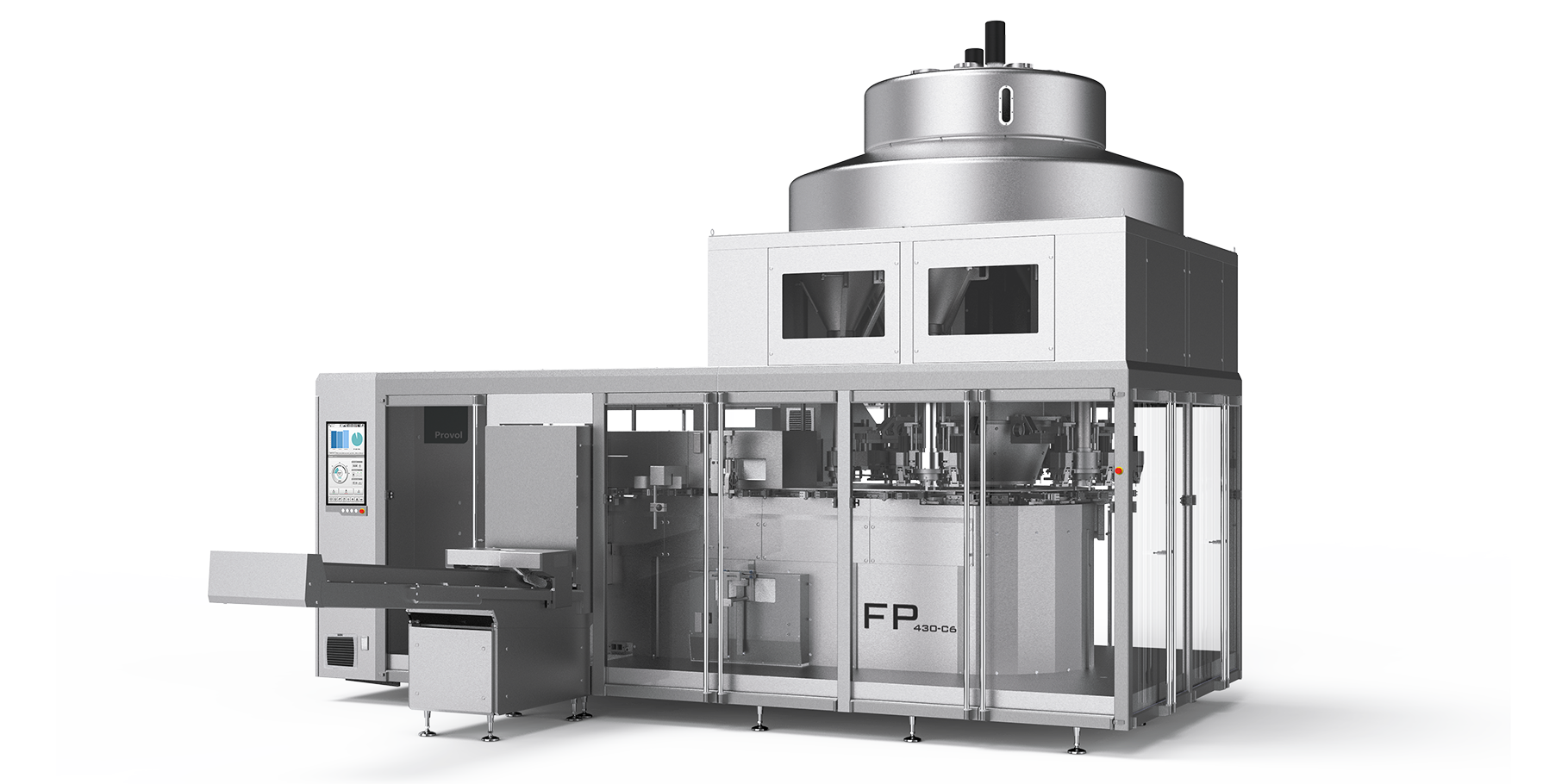

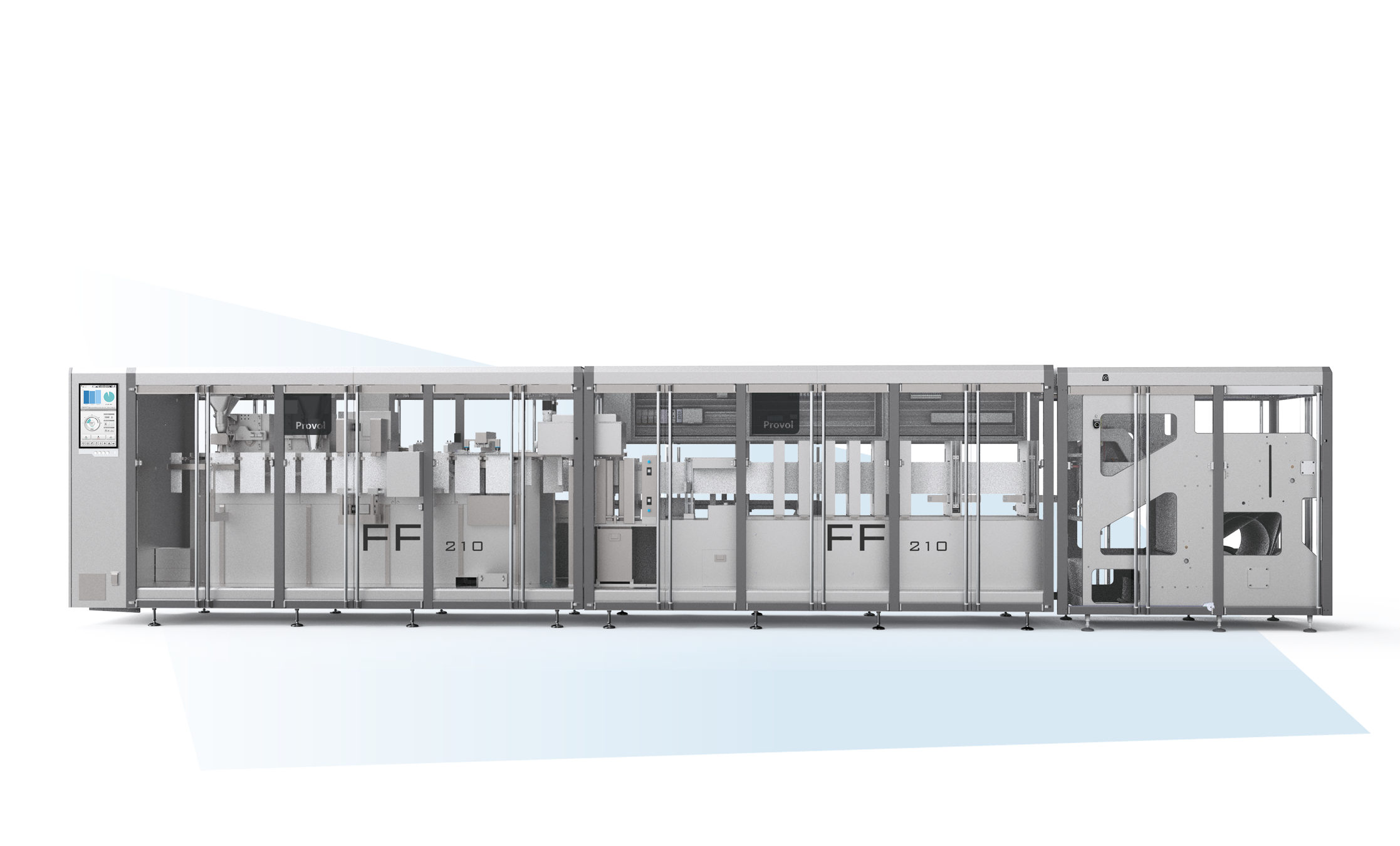

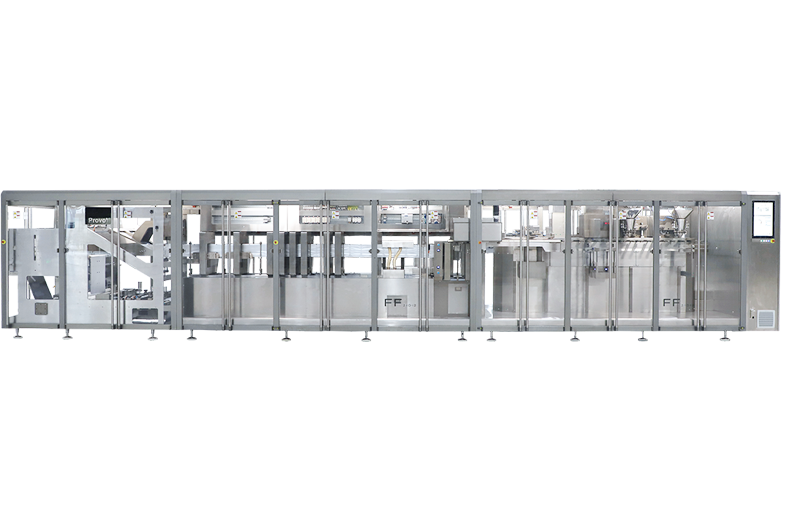

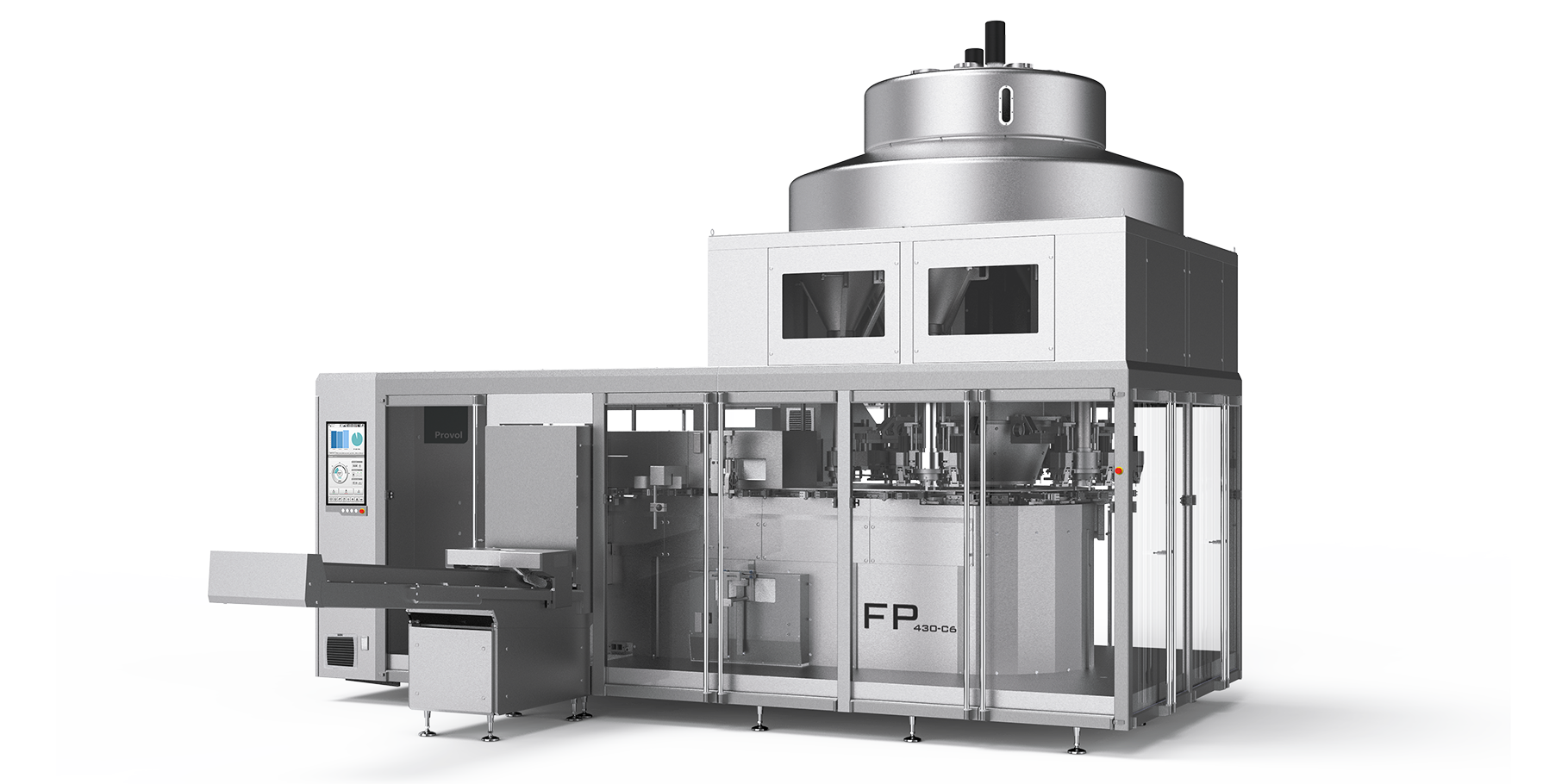

We have been specialising in the design and manufacture of high performance horizontal packaging machinery for medium and large products, with a focus on the main industries we work with concentrating on pet food, grain and oil products such as pet food, flour, pharmaceuticals, etc. Other industries also have numerous solid (granules, powders), liquid, mixed material or individual packages. Using our many years of experience in the design and manufacture of packaging machinery, we are able to offer a customised service, offering custom packaging machines for packaging applications outside our standard range of machinery.

The main advantages and benefits of automating your packaging plant are described below.

For example, it will allow you to increase the efficiency of your staff and enable you to cope successfully with possible peaks in demand; you will be able to work more and in less time in a safer and more profitable way, thus significantly increasing your production capacity and quickly recouping your investment in our packaging equipment.

On the other hand, in terms of occupational safety, the risk of accidents is also significantly reduced by reducing the number of stages and processes in which operators are involved, which is a benefit for any company.

Thus, in plants equipped with our state-of-the-art custom packaging machines, all those repetitive tasks that add little value are removed from the equation.

Another key aspect to remember is that with our machines you will save significantly on packaging materials and reduce production costs, but without having to give up the highest quality packaging.

And speaking of quality, remember that all our machines are designed to provide the best possible quality packaging, even allowing you to add customised graphics and logos!

Reliable and efficient: using a custom packaging machine to package your products gives you more reliable results and a more efficient process than manual filling. Every product will be packaged in the same way.

Low transport costs: Packaging products that are too small or too large can damage the item, waste packaging material and increase transport costs. custom packaging machines can create the right size packaging for the product, ensuring that the item is safe and cost effective during transport.

Co-development: custom packaging machine automation solutions encourage collaboration between design and manufacturing. This process reduces problems and production delays, so you can get your custom packaging machine faster.

By machine: See our full range of case packers, case/tray packers as well as robots and integrated solutions.

By product: this page is organised by products such as pasta and cereals, confectionery, frozen foods and pharmaceuticals. There you will find integrated packaging solutions that can be tailored to your unique application.

By packaging type :The page leads you to the best type of machine for your specific packaging situation.

Machine design: Our team will design your automated packaging machine. We will create concept renderings, documentation and other specifications.

Engineering: Our design and manufacturing process utilises best-in-class software and technology to ensure quality.

Development: Massman will identify the tools and technology required to create your customised machine.

Control Systems: Our robot solutions can include virtually any standard or engineered control system you specify, such as wireless remote control options.

Motion control: Massman Automation Designs will ensure that your custom machine has the best components and architecture. Once your machine has been installed, we can provide further support, such as on-site service repairs or formal equipment training.

We have many years of experience in tackling a wide range of packaging challenges. Using this experience and industry knowledge, we customise our integrated packaging machinery to suit each customer's unique product, application and operating environment.

Whether you need a standard single machine or a highly customized system solution, we can offer you our professional packaging solution to meet your In the whole production line integration project, we can also help you to choose proper third-party equipment and provide project planning and corresponding management system to ensure that you have optimized production system.

We are always 100% involved in every project and customer, supporting them throughout the purchase and installation process and providing them with the best technical and after-sales service; we fully understand what is involved in this type of investment and a fundamental part of our work involves minimising any errors in every sense, gaining their trust, building long lasting relationships and successfully meeting their packaging needs.

Our skilled engineers build complete integrated packaging systems that can be customized packaging machines according to the customer's needs. contact us now!

Why automate your packaging line now and make your plant

The main advantages and benefits of automating your packaging plant are described below.

For example, it will allow you to increase the efficiency of your staff and enable you to cope successfully with possible peaks in demand; you will be able to work more and in less time in a safer and more profitable way, thus significantly increasing your production capacity and quickly recouping your investment in our packaging equipment.

On the other hand, in terms of occupational safety, the risk of accidents is also significantly reduced by reducing the number of stages and processes in which operators are involved, which is a benefit for any company.

Thus, in plants equipped with our state-of-the-art custom packaging machines, all those repetitive tasks that add little value are removed from the equation.

Another key aspect to remember is that with our machines you will save significantly on packaging materials and reduce production costs, but without having to give up the highest quality packaging.

And speaking of quality, remember that all our machines are designed to provide the best possible quality packaging, even allowing you to add customised graphics and logos!

Advantages of the custom packaging machine

Reliable and efficient: using a custom packaging machine to package your products gives you more reliable results and a more efficient process than manual filling. Every product will be packaged in the same way.

Low transport costs: Packaging products that are too small or too large can damage the item, waste packaging material and increase transport costs. custom packaging machines can create the right size packaging for the product, ensuring that the item is safe and cost effective during transport.

Co-development: custom packaging machine automation solutions encourage collaboration between design and manufacturing. This process reduces problems and production delays, so you can get your custom packaging machine faster.

custom packaging machine range

By machine: See our full range of case packers, case/tray packers as well as robots and integrated solutions.

By product: this page is organised by products such as pasta and cereals, confectionery, frozen foods and pharmaceuticals. There you will find integrated packaging solutions that can be tailored to your unique application.

By packaging type :The page leads you to the best type of machine for your specific packaging situation.

custom packaging machine services

Machine design: Our team will design your automated packaging machine. We will create concept renderings, documentation and other specifications.

Engineering: Our design and manufacturing process utilises best-in-class software and technology to ensure quality.

Development: Massman will identify the tools and technology required to create your customised machine.

Control Systems: Our robot solutions can include virtually any standard or engineered control system you specify, such as wireless remote control options.

Motion control: Massman Automation Designs will ensure that your custom machine has the best components and architecture. Once your machine has been installed, we can provide further support, such as on-site service repairs or formal equipment training.

We have many years of experience in tackling a wide range of packaging challenges. Using this experience and industry knowledge, we customise our integrated packaging machinery to suit each customer's unique product, application and operating environment.

Whether you need a standard single machine or a highly customized system solution, we can offer you our professional packaging solution to meet your In the whole production line integration project, we can also help you to choose proper third-party equipment and provide project planning and corresponding management system to ensure that you have optimized production system.

We are always 100% involved in every project and customer, supporting them throughout the purchase and installation process and providing them with the best technical and after-sales service; we fully understand what is involved in this type of investment and a fundamental part of our work involves minimising any errors in every sense, gaining their trust, building long lasting relationships and successfully meeting their packaging needs.

Our skilled engineers build complete integrated packaging systems that can be customized packaging machines according to the customer's needs. contact us now!