What is Horizontal Form-Fill-Seal (HFFS) ?

Category:Industry Market

Publication Time:2023-01-16

Author:RN-Z

Page view:

Horizontal fill seal machines (flowrap) are probably the most usual packaging maker in the food sector. They are ideal for singular items and are offered from beginning to completely automated high speed lines.

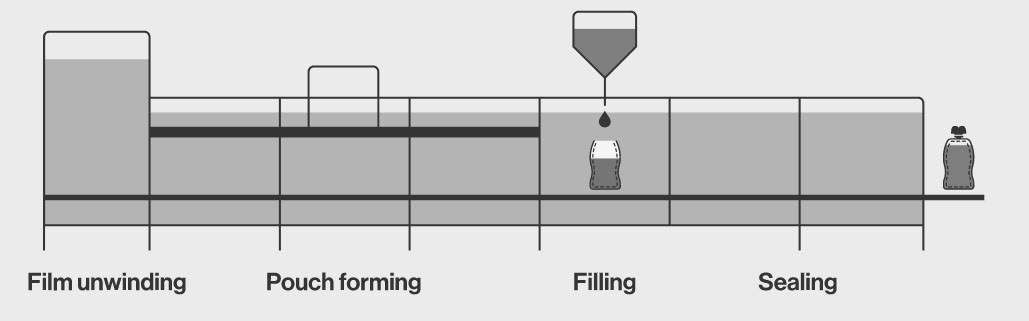

Horizontal Form-Fill-Seal tools can both generate a pouch from roll supply movie and also spout as well as top settings up, and load it in the same operation. The film or laminate travels via the device in a horizontal direction, which offers the device the "horizontal" description. This procedure accounts for all parts of producing a full pouch item, from film taking a break, bag forming, loading as well as sealing, as seen listed below. A benefit of HFFS is that it optimizes the overall price of possession as well as enables even moreadaptability in sizes and shapes in production. It likewise supplies the producer with total control of their packaging procedure. Pouches/sachets that are made using HFFS technology are less costly than Pre-made ones.

Horizontal Form-Fill-Seal tools can both generate a pouch from roll supply movie and also spout as well as top settings up, and load it in the same operation. The film or laminate travels via the device in a horizontal direction, which offers the device the "horizontal" description. This procedure accounts for all parts of producing a full pouch item, from film taking a break, bag forming, loading as well as sealing, as seen listed below. A benefit of HFFS is that it optimizes the overall price of possession as well as enables even moreadaptability in sizes and shapes in production. It likewise supplies the producer with total control of their packaging procedure. Pouches/sachets that are made using HFFS technology are less costly than Pre-made ones.

How it functions?

The procedure of circulation wrapping/flow packing, or otherwise known a horizontal form-fill as well as seal (HFFS) is the process of making a horizontal bag from a single roll of film. Heat is applied to the bottom or top and ends of the film to form a hermetically sealed, versatile plan with the end product safeguarded within. Circulation wrap product packaging is utilized for a variety of foodstuff and is an extremely cost-effective, high-speed service for primary packaging of final products.

Sealing - Heat Seal: Hermetic seals despite seal area contamination.Seal and cool at the exact same step, enabling product packaging for a circular economic climate.

Based upon electric resistance - Easy design, basic upkeep.

Ultra Sonic - Based on ultra-sound regularity.

Induction Seal - Based on electro-magnetic resistance.

essential benefits

Can run a series of films from solitary internet to high barrier laminates

Beginning to fully automated high speed lines with infeed

Fast changeover times in between item and product

Ultra sonic scaling jaws offered

Can load a variety of items

Easy to use and also preserve

HFFS devices are really functional in their packaging variety and also can run most kinds of film.

We can offer a Packaging Engineer, FREE of fee, to make sure customers are optimising line efficiencies, using the maximum packaging movie for their product.

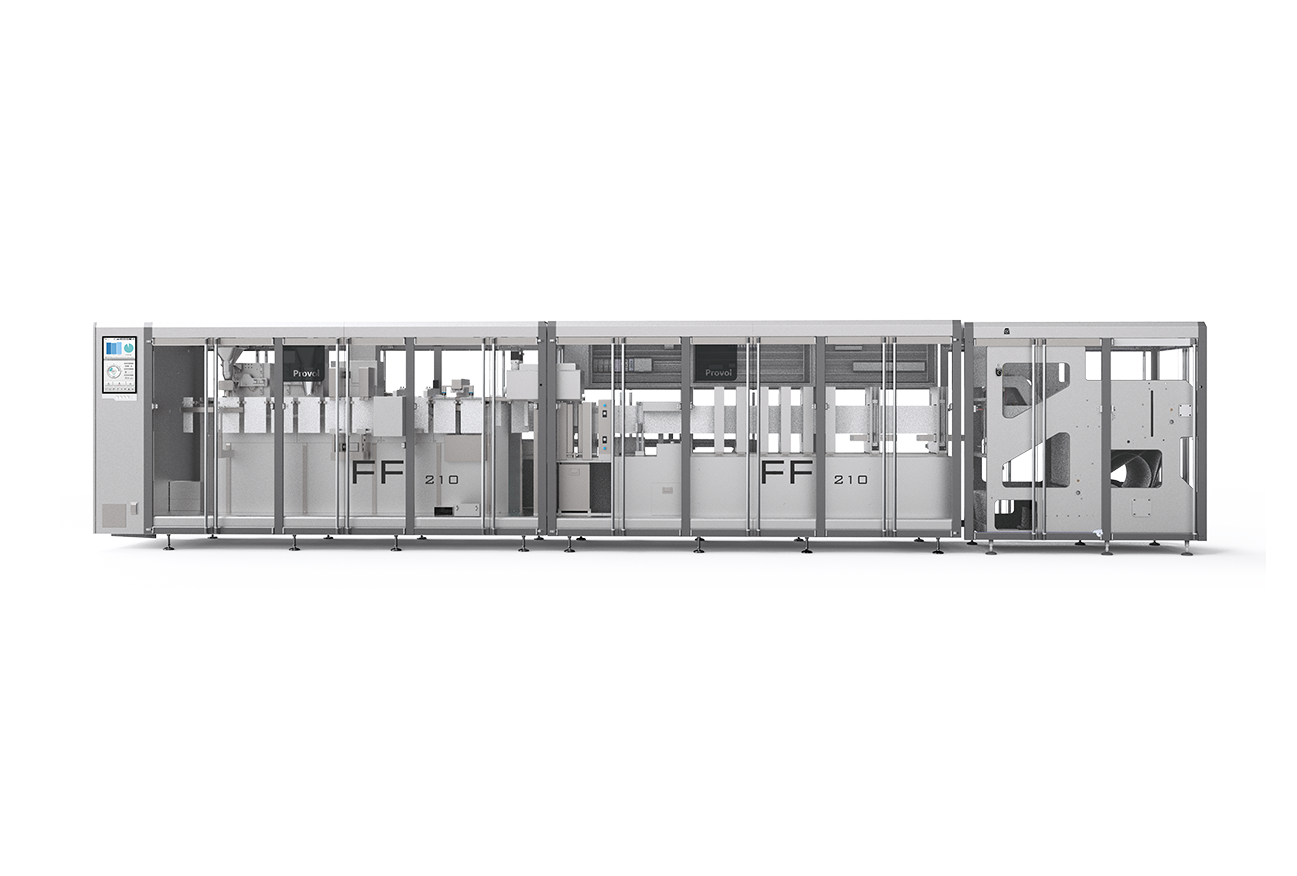

Provol has the widest series of Horizontal Form Fill as well as Seal devices in the marketplace. Our machines cover all the applications and also are customized to be adjusted to our consumers' demands. The layout is based on the modular structure construction, composed of three independent modules: unwinder, pouch creating and dosing-sealing. These components are available in several versions according to the item to be filled up. By doing this we always offer our consumers the machines that match better their demands.